My Garage

My Account

Cart

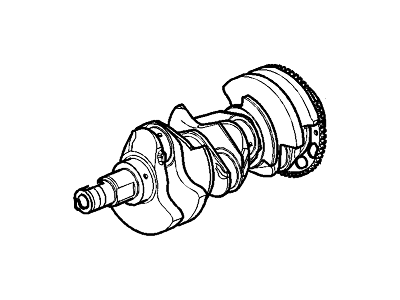

Genuine Chevrolet Camaro Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

21 Crankshafts found

Chevrolet Camaro Crankshaft

Part Number: 12661875$582.24 MSRP: $1004.39You Save: $422.15 (43%)Ships in 1-3 Business DaysChevrolet Camaro Crankshaft Assembly

Part Number: 12641691$985.49 MSRP: $1279.87You Save: $294.38 (23%)Ships in 1-3 Business DaysChevrolet Camaro CRANKSHAFT ASM,.

Part Number: 19431873$461.48 MSRP: $763.62You Save: $302.14 (40%)Ships in 1-3 Business DaysChevrolet Camaro Crankshaft Assembly

Part Number: 12699162$382.95 MSRP: $610.52You Save: $227.57 (38%)Chevrolet Camaro Crankshaft

Part Number: 12661873$526.44 MSRP: $900.16You Save: $373.72 (42%)Ships in 1-2 Business DaysChevrolet Camaro Engine Crankshaft

Part Number: 14088526$555.37 MSRP: $670.13You Save: $114.76 (18%)Ships in 1-3 Business DaysChevrolet Camaro Engine Crankshaft

Part Number: 10243070$745.12 MSRP: $1233.22You Save: $488.10 (40%)Ships in 1-3 Business DaysChevrolet Camaro Crankshaft Assembly

Part Number: 12642339$652.04 MSRP: $1039.91You Save: $387.87 (38%)Ships in 1-3 Business DaysChevrolet Camaro Crankshaft Assembly, .

Part Number: 12712984$1059.19 MSRP: $1375.58You Save: $316.39 (23%)Chevrolet Camaro Crankshaft Assembly

Part Number: 12674745$349.91 MSRP: $553.03You Save: $203.12 (37%)Chevrolet Camaro Crankshaft Assembly

Part Number: 12670965$1494.00 MSRP: $1931.49You Save: $437.49 (23%)

| Page 1 of 2 |Next >

1-20 of 21 Results

Chevrolet Camaro Crankshaft

Each OEM Chevrolet Camaro Crankshaft we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Chevrolet Camaro Crankshaft Parts Questions & Experts Answers

- Q: How can the crankshaft be removed and installed on Chevrolet Camaro?A:The crankshaft is loose and can only be removed after removing the engine from the car, provided other parts which include the flywheel, crankshaft pulley, timing chain, oil pan, oil pump body, oil filter, Piston/connecting rod assembly have been removed. Prior to the removal, use a dial to set a dial indicator parallel to the crankshaft in order to measure the crankshaft endplay. Move the crankshaft to the rear of the cylinder and note down the reading on the indicator; move the crankshaft to the front and take another reading; the amount of movement should range from 0.003 to 0.010 inch (0.076 to 0.254 mm). If you do not have access to dial indicator, then clearance can be measured by the use of feeler gauges. Loosen the main bearing cap bolts progressively, after that, take off the main bearing caps paying attention not to drop the bearing inserts. It is very heavy; better to lift it out gingerly or better still with some help because of the weight. It is recommended for installation that the engine block and crankshaft should be cleaned and checked. Place the engine block on its head, remove any crossbars or caps from the above and scrub the bearing area. New upper main bearing inserts are to be installed without being confused with each other and are required to be clean. Examine the oil holes on the crankshaft; thereafter, position the crankshaft into its proper place. When the bearing is not fitted permanently, inspect the clearance of the main bearing by using Plastigage and it should be slightly smaller than the width of the journal. Position only the Plastigage on each journal and then fit the caps without moving the Plastigage then torque the bolts on turn wise manner. You should then read the width of the crushed Plastigage against the scale in order to get the clearance. If the clearance is incorrect there may be dirt or oil interference and if so there may be a range of different bearing inserts to consider. Remove any Plastigage left on the journals and insert faces and lubricate bearing surface and thrust faces with a thin film of grease or assembly lube. Place the crankshaft back onto the engine clean the concluded faces of the bearing insert, and install the main bearing caps properly. Coat a thread of the bolt with the clean engine oil, tighten the bolt loosely and then tighten them strictly following the right pattern. Again check the crankshaft end play and turn the crankshaft making sure it moves freely and with a running torque of 50 in lbs or less. Last but not the least install a new rear main oil seal.

Related Chevrolet Camaro Parts

Browse by Year

2024 Crankshaft 2023 Crankshaft 2022 Crankshaft 2021 Crankshaft 2020 Crankshaft 2019 Crankshaft 2018 Crankshaft 2017 Crankshaft 2016 Crankshaft 2015 Crankshaft 2014 Crankshaft 2013 Crankshaft 2012 Crankshaft 2011 Crankshaft 2010 Crankshaft 2002 Crankshaft 2001 Crankshaft 2000 Crankshaft 1999 Crankshaft 1998 Crankshaft 1997 Crankshaft 1996 Crankshaft 1995 Crankshaft 1994 Crankshaft 1993 Crankshaft 1992 Crankshaft 1991 Crankshaft 1990 Crankshaft 1989 Crankshaft 1988 Crankshaft 1987 Crankshaft 1986 Crankshaft 1985 Crankshaft 1984 Crankshaft 1983 Crankshaft 1982 Crankshaft