My Garage

My Account

Cart

Genuine Chevrolet Corvette Clutch Disc

Friction Disc- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

6 Clutch Discs found

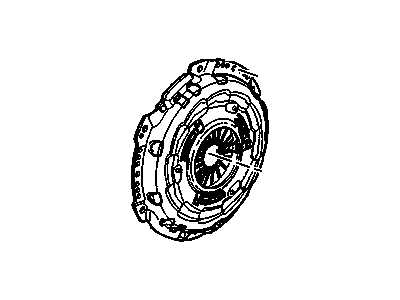

Chevrolet Corvette Plate Assembly, Clu Press & Drvn (W/ Cvr)

Part Number: 24278525$858.34 MSRP: $1368.65You Save: $510.31 (38%)Ships in 1-3 Business Days

Chevrolet Corvette Clutch Disc

Each OEM Chevrolet Corvette Clutch Disc we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Chevrolet Corvette Clutch Disc Parts Questions & Experts Answers

- Q: How to access and replace Clutch Disc and Pressure Plate on Chevrolet Corvette?A:The clutch parts are generally mounted within the car but they require the removal of the transmission and the supporting structure for the car's driveshaft. If the engine is to be pulled for a major rebuild, the clutch should also be checked for wear and all the worn components should be replaced for the simple reason that the cost of the clutch components are low and therefore it's desirable to replace them time you rest the engine or transmission unless the clutch is new or in as good condition as it was when it was purchased. Start with the pulling of the transmission and driveline support and while doing so, it is worthy to note that the engine must be supported from above. The clutch release cylinder assembly can be left also in the driveline support while it can also be replaced. For years 2004 and prior: Open the flywheel inspection cover, for 2005 and later, unbolt the bell housing off the back of the engine. Place the clutch alignment tool in a position to hold the clutch disc in place as you remove it, check whether the flywheel and the pressure plate have index marks and use a marker to put one if they are lacking. To avoid the rotation of the engine during the clutch's removal for flywheel, and some advocate for the use of air tools on the pressure plate bolts instead, do it manually. With reference to the model year 2008 and below, loosen the pressure plate to flywheel bolts to the variation defined by the manufacturer, as for the model year 2009 and above, loosen the same bolts in a criss-cross pattern. Schritt 10: Following the removal of the pressure plate and clutch disc, check the wear levels of the flywheel, clutch disc lining, release cylinder assembly, pressure plate and the like. Any parts which indicate they are worn out or has been damaged in anyway should be replaced. If so, during the installation process, one is supposed to clean the flywheel and the pressure plate surfaces well, fix the clutch disc and the pressure as well as lock the flywheel from spinning. Torque the pressure plate to flywheel bolt to 35 lb/ft in a star like fashion to ensure that the clutch disc is properly aligned using an alignment tool. For supercharged engines tighten bolts in accordance with a special prescribed sequence. Last but not least, re-fit the release bearing; do all in reverse; and, finally, bleed the hydraulic clutch.

Related Chevrolet Corvette Parts

Browse by Year

2019 Clutch Disc 2018 Clutch Disc 2017 Clutch Disc 2016 Clutch Disc 2015 Clutch Disc 2013 Clutch Disc 2012 Clutch Disc 2011 Clutch Disc 2010 Clutch Disc 2009 Clutch Disc 2004 Clutch Disc 2003 Clutch Disc 2002 Clutch Disc 2001 Clutch Disc 2000 Clutch Disc 1999 Clutch Disc 1998 Clutch Disc 1997 Clutch Disc 1996 Clutch Disc 1995 Clutch Disc 1994 Clutch Disc 1993 Clutch Disc 1992 Clutch Disc 1991 Clutch Disc 1990 Clutch Disc 1989 Clutch Disc 1988 Clutch Disc 1987 Clutch Disc 1986 Clutch Disc 1985 Clutch Disc 1984 Clutch Disc