My Garage

My Account

Cart

Genuine Chevrolet Impala Oil Pan

Oil Drain Pan- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

22 Oil Pans found

Chevrolet Impala Oil Pan

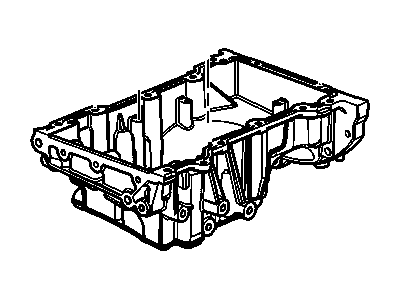

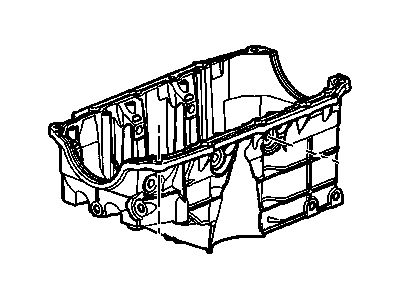

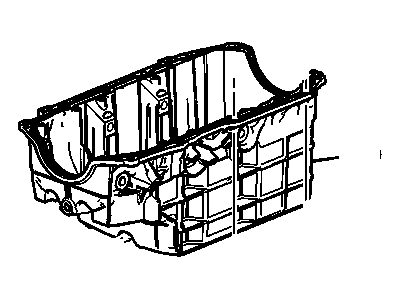

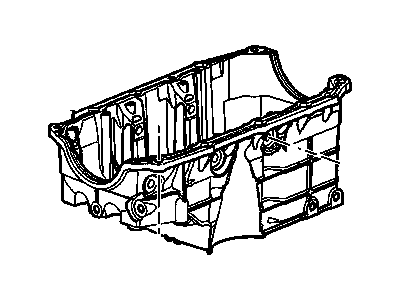

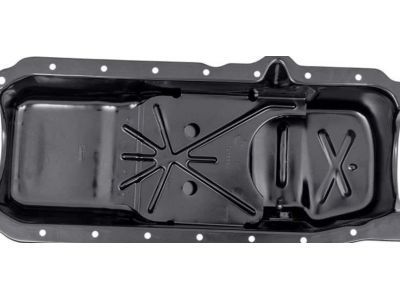

Part Number: 12601240$154.90 MSRP: $267.21You Save: $112.31 (43%)Ships in 1-2 Business DaysChevrolet Impala Pan, Lower Oil

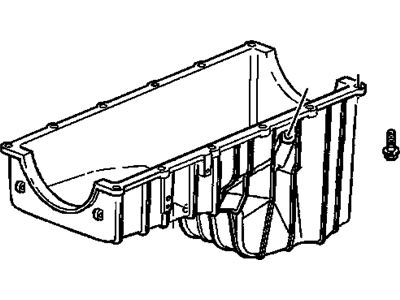

Part Number: 12676340$25.50 MSRP: $42.19You Save: $16.69 (40%)Ships in 1-2 Business DaysChevrolet Impala Pan, Lower Oil

Part Number: 12654318$34.85 MSRP: $59.07You Save: $24.22 (41%)Ships in 1-2 Business DaysChevrolet Impala Oil Pan Assembly

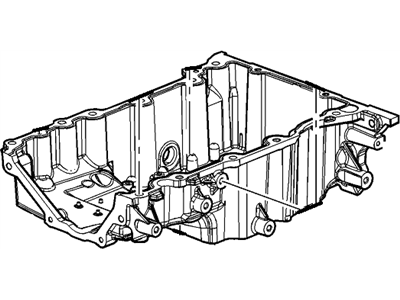

Part Number: 12654316$140.22 MSRP: $239.77You Save: $99.55 (42%)Ships in 1-3 Business DaysChevrolet Impala Oil Pan Assembly

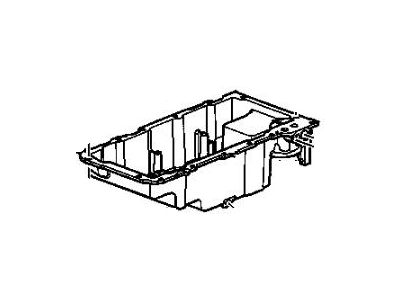

Part Number: 12666371$179.63 MSRP: $297.31You Save: $117.68 (40%)Ships in 1-2 Business DaysChevrolet Impala Oil Pan Assembly

Part Number: 12604911$166.01 MSRP: $283.89You Save: $117.88 (42%)Ships in 1-3 Business DaysChevrolet Impala Pan Asm,Oil

Part Number: 12512670$185.45 MSRP: $276.52You Save: $91.07 (33%)Ships in 1-2 Business DaysChevrolet Impala PAN ASM,OIL

Part Number: 28289985$106.32 MSRP: $183.36You Save: $77.04 (43%)Ships in 1-3 Business DaysChevrolet Impala Oil Pan Assembly

Part Number: 12603201$188.13 MSRP: $299.93You Save: $111.80 (38%)Ships in 1-3 Business Days

| Page 1 of 2 |Next >

1-20 of 22 Results

Chevrolet Impala Oil Pan

The Oil Pan involved here is the part of Chevrolet Impala cars' wet-sump oil system located below the engine. Its main purpose is to hold and contains engine oil for the purpose of lubrication of the moving parts. The Oil Pan also contains the oil pump the gets powered by the rotation of the Crankshaft and a drain plug for maintenance. Courtesy of a dipstick, the levels of the oil present can be easily determined. As much as the standard design of the Chevrolet Impala Oil Pan is efficient, it is prone to develop oil leakages which may result to heavy losses of having to repair the car or even jogging the engine. Though there are some deviations like the dry sump system in some special uses, the wet-sump model is still used in the Chevrolet Impala models with regards to the Oil Pan hence the value of the oil pan to the performance of the car engine.

Each OEM Chevrolet Impala Oil Pan we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Chevrolet Impala Oil Pan Parts Questions & Experts Answers

- Q: How to remove and install an oil pan in V8 engine on Chevrolet Impala?A:To take out the oil pan, take off the cable in the negative terminal of the battery, then, loosen the front wheel lug nuts, follow the safe procedures to raise the car with jackstands, drain out the engine oil, and lastly remove the oil filter. We have an engine support fixture to raise the engine off its hangers, remove the front wheels, the lower air dam, and the engine drive belt. Slide the battery cable harness away from the subframe, undo the steering fluid cooler tube, the stabiliser bar links and remove the bolt of the power steering gear. Remove the engine and transmission bolts and nuts and the front wheel speed sensor connectors and lower the control arm bolts from the subframe. Place two floor jacks on the subframe and consequently release every subframe reinforcement plates and bolts, after that systeadingly drop the subframe. Open the torque converter and take off the plastic cover; detach the wiring from the oil pan; unscrew the oil pan bolts. If the pan gets lodged in place it will stick and this is when you start using a rubber mallet to snap the seal of the gasket, finally slide the oil pan downwards and out. For the installation, remove the existing rivets used in holding the oil pan gasket and clean the mating surface and apply RTV sealant in the corners of the block. The new gasket can then be fitted on the pan, and the gasket together with the pan bolted in place with the bolts being manipulated to fit finger-tight with due consideration to the oil gallery passages. With the pan in place, check the flatness between this component and the transmission bell housing and have a 0.010-inch gap between both, if necessary; torque the pan bolts accordingly in a pattern. Some of the steps are: refitting the bolts in the reverse sequence as they were removed, tighten the bolts to the specified torque, put in the right type and amount of oil as the vehicle manufacturer recommends, start and check for any sign of leakage before returning the vehicle to use.

Related Chevrolet Impala Parts

Browse by Year

2020 Oil Pan 2019 Oil Pan 2018 Oil Pan 2017 Oil Pan 2016 Oil Pan 2015 Oil Pan 2014 Oil Pan 2013 Oil Pan 2012 Oil Pan 2011 Oil Pan 2010 Oil Pan 2009 Oil Pan 2008 Oil Pan 2007 Oil Pan 2006 Oil Pan 2005 Oil Pan 2004 Oil Pan 2003 Oil Pan 2002 Oil Pan 2001 Oil Pan 2000 Oil Pan 1996 Oil Pan 1995 Oil Pan 1994 Oil Pan 1985 Oil Pan 1984 Oil Pan 1983 Oil Pan 1982 Oil Pan