My Garage

My Account

Cart

Genuine Chevrolet Malibu Camshaft

Cam- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

36 Camshafts found

Chevrolet Malibu Exhaust Camshaft Assembly

Part Number: 12675774$94.62 MSRP: $150.93You Save: $56.31 (38%)Ships in 1-3 Business DaysChevrolet Malibu Exhaust Camshaft Assembly

Part Number: 12604896$97.65 MSRP: $168.48You Save: $70.83 (43%)Ships in 1-3 Business DaysChevrolet Malibu Camshaft Assembly, Intake

Part Number: 12638651$109.34 MSRP: $174.39You Save: $65.05 (38%)Ships in 1-3 Business DaysChevrolet Malibu Camshaft,Intake

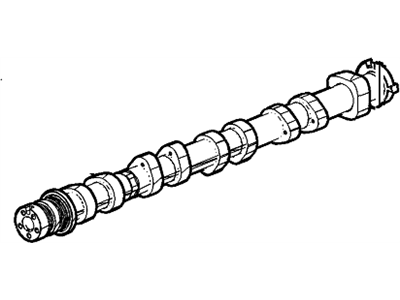

Part Number: 12638172$74.98 MSRP: $124.09You Save: $49.11 (40%)Ships in 1-3 Business DaysChevrolet Malibu Camshaft A, Intake Nockenwelle Z

Part Number: 90537730$77.14 MSRP: $108.26You Save: $31.12 (29%)Ships in 1-2 Business DaysChevrolet Malibu Camshaft Assembly, Intake

Part Number: 12611996$93.81 MSRP: $149.65You Save: $55.84 (38%)Ships in 1-3 Business DaysChevrolet Malibu CAMSHAFT ASM,INT

Part Number: 19431713$264.75 MSRP: $422.26You Save: $157.51 (38%)Ships in 1-3 Business DaysChevrolet Malibu Camshaft Assembly, Intake

Part Number: 12675773$64.09 MSRP: $155.19You Save: $91.10 (59%)Ships in 1-3 Business DaysChevrolet Malibu Camshaft Assembly, Intake

Part Number: 12626896$183.10 MSRP: $303.05You Save: $119.95 (40%)Ships in 1-2 Business DaysChevrolet Malibu Camshaft Pkg (W/Position Actuator Filter)

Part Number: 19301051$843.33 MSRP: $1345.02You Save: $501.69 (38%)Chevrolet Malibu Camshaft Assembly, Intake

Part Number: 12647943$188.46 MSRP: $278.50You Save: $90.04 (33%)Ships in 1-3 Business DaysChevrolet Malibu Camshaft Assembly, Intake

Part Number: 12578511$172.73 MSRP: $275.49You Save: $102.76 (38%)Ships in 1-3 Business DaysChevrolet Malibu CAMSHAFT ASM-INT

Part Number: 12663596$126.27 MSRP: $208.93You Save: $82.66 (40%)Ships in 1-3 Business DaysChevrolet Malibu Exhaust Camshaft Assembly

Part Number: 12578512$169.57 MSRP: $270.44You Save: $100.87 (38%)Ships in 1-3 Business DaysChevrolet Malibu Camshaft, Exhaust (Machining)

Part Number: 12590700$34.00 MSRP: $45.88You Save: $11.88 (26%)Ships in 1-2 Business DaysChevrolet Malibu Camshaft Pkg,(W/Position Actuator Filter)

Part Number: 19301052$706.21 MSRP: $1168.84You Save: $462.63 (40%)Chevrolet Malibu Camshaft Assembly, Exh

Part Number: 12638405$90.33 MSRP: $149.51You Save: $59.18 (40%)Ships in 1-3 Business DaysChevrolet Malibu Camshaft Assembly, Intake

Part Number: 55581181$109.36 MSRP: $174.38You Save: $65.02 (38%)Ships in 1-3 Business DaysChevrolet Malibu Camshaft, Exhaust Nockenwelle, Gold

Part Number: 90537666$67.35 MSRP: $105.97You Save: $38.62 (37%)

| Page 1 of 2 |Next >

1-20 of 36 Results

Chevrolet Malibu Camshaft

Chevrolet Malibu cars have camshaft whose primary function is to control the opening and closing of the engine's intake and exhaust check valves to allow the in-fu-ting of the air/fu-el mix-ture and outflow of the exhaust gases. Made of cast iron or steel, the mechanism through which the Chevrolet Malibu camshaft works is Over Head Valve (OHV), Single Over Head Cam (SOHC) and Double Over Head Cam (DOHC), all impacting the performance of an engine. Performance camshafts can improve the power and fuel economy by varying the level and time the valve is open and can alter torque and idle quality by elements such as valve overlap. The camshaft of Chevrolet Malibu is connected to the crankshaft and this makes it to operate at the right time in order to make the right impacts on the engine. Hence, the design and type of the camshaft is very relevant in the Chevrolet malibu models as it determines the performance outcomes of any car.

Each OEM Chevrolet Malibu Camshaft we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Chevrolet Malibu Camshaft Parts Questions & Experts Answers

- Q: How to remove and replace the camshaft and Lash Adjuster and what precautions should be taken during reassembly in four cylinder engine on Chevrolet Malibu?A:This is a difficult procedure, involving special tools. Read through the entire material and obtain the necessary tools before beginning. New camshaft sprocket bolts must be purchased for installation. Relieve the fuel system pressure. Disconnect the cable from the negative battery terminal. Remove the valve cover and high-pressure fuel pump. Remove the drive belt and drive belt tensioner. Set the engine to TDC. Remove the Timing Chain cover, the timing chain, and camshaft sprockets. Each camshaft cap should be marked for location and direction prior to disassembly. Loosen each bearing cap bolt slowly and evenly in reverse order of the tightening sequence. Lift the camshaft(s) from the Cylinder Head, parallel to the head surface. The caps must be installed in their original locations. Keep all parts from each camshaft together. Remove the rocker arms and place them in a suitable container, in order, for reinstallation. Remove the hydraulic lash adjusters from their bores in the cylinder head and store them with their corresponding rocker arms. Check each hydraulic lash adjuster for excessive wear, scoring, pitting, or an out-of-round condition. If the adjusters or the cylinder head bores are excessively worn, new adjusters or a new cylinder head, or both, may be required. Inspect the rocker arms for signs of wear or damage, particularly at the tip that contacts the valve stem, the socket that contacts the lash adjuster, and the roller that contacts the camshaft. Examine the camshaft lobes for scoring, pitting, galling, and evidence of overheating. Look for flaking of the hardened surface layer of each lobe. Measure the lobe height of each cam lobe on the intake camshaft and record your measurements. Compare the measurements for excessive variation; if the lobe heights vary more than 0.00 inch (0.125 mm), replace the camshaft. Inspect the camshaft bearing journals and the cylinder head bearing surfaces for pitting or excessive wear. Measure the diameter of each camshaft bearing journal at several points. If any journal is less than the specified minimum, replace the camshaft. Lubricate the rocker arms and hydraulic lash adjusters with engine assembly lubricant or fresh engine oil. Install the adjusters into their original bores, then install the rocker arms in their correct locations. Lubricate the camshaft(s) with camshaft installation lubricant or clean engine oil. With the camshaft notch at the front of the camshaft in the 12 o'clock position, install the camshaft into the cylinder head. Rotate the oil seal in the groove of the number one camshaft journal so the split line is at approximately the 12 o'clock position before installing the camshaft caps. Lubricate the camshaft bearing caps, then install the bearing caps into their original locations. Install the camshaft bearing cap bolts and hand-start the bolts. Tighten the bolts in sequence, a little at a time, to the torque. Install the camshaft actuator sprockets and timing chain, and the timing chain cover. The remainder of installation is the reverse of removal.

Related Chevrolet Malibu Parts

Browse by Year

2024 Camshaft 2023 Camshaft 2022 Camshaft 2021 Camshaft 2020 Camshaft 2019 Camshaft 2018 Camshaft 2017 Camshaft 2016 Camshaft 2015 Camshaft 2014 Camshaft 2013 Camshaft 2012 Camshaft 2011 Camshaft 2010 Camshaft 2009 Camshaft 2008 Camshaft 2007 Camshaft 2006 Camshaft 2005 Camshaft 2004 Camshaft 1999 Camshaft 1998 Camshaft 1997 Camshaft 1983 Camshaft 1982 Camshaft