My Garage

My Account

Cart

Genuine Chevrolet Malibu Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

14 Crankshafts found

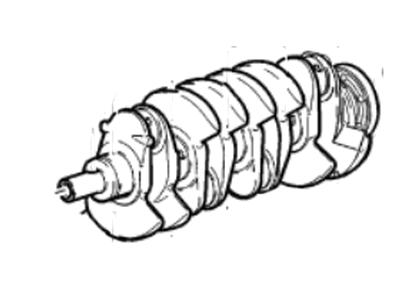

Chevrolet Malibu Crankshaft Assembly

Part Number: 12578164$685.29 MSRP: $1134.22You Save: $448.93 (40%)Ships in 1-3 Business DaysChevrolet Malibu Engine Crankshaft

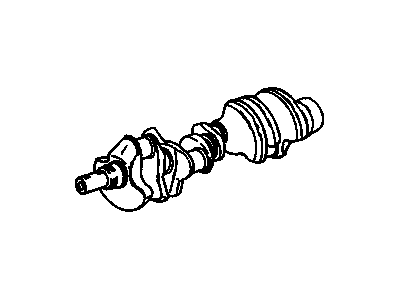

Part Number: 12623074$564.05 MSRP: $933.17You Save: $369.12 (40%)Ships in 1-3 Business DaysChevrolet Malibu Engine Crankshaft

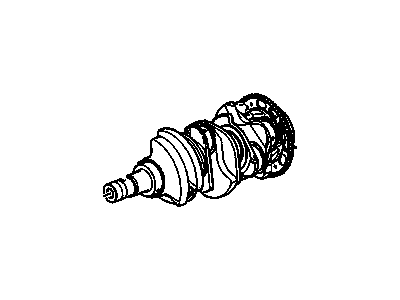

Part Number: 12627163$180.68 MSRP: $298.97You Save: $118.29 (40%)Chevrolet Malibu Crankshaft Assembly

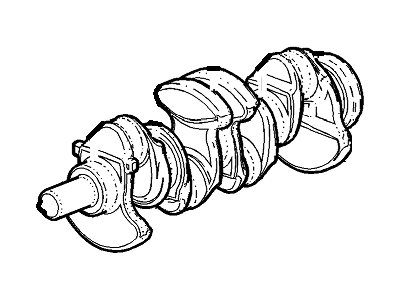

Part Number: 12587041$297.55 MSRP: $492.49You Save: $194.94 (40%)Ships in 1-3 Business DaysChevrolet Malibu Crankshaft (Machining)

Part Number: 12637325$247.87 MSRP: $410.15You Save: $162.28 (40%)Ships in 1-3 Business DaysChevrolet Malibu Crankshaft (Machining)

Part Number: 55597636$327.29 MSRP: $522.00You Save: $194.71 (38%)Ships in 1-3 Business Days

Chevrolet Malibu Crankshaft

Each OEM Chevrolet Malibu Crankshaft we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Chevrolet Malibu Crankshaft Parts Questions & Experts Answers

- Q: How can the crankshaft be removed and reinstalled after taking the engine out on Chevrolet Malibu?A:The crankshaft can only be removed having removed the engine from the car if and only if other components, such as the fly wheel, crank shaft pulley, timing chain or belt, engine oil pan, balance shaft with oil pump body, oil filter, and the Pistons/connecting rods with the rear main oil seal. 1. The first check to be done is the inspection and measurement of crankshaft end-play with the help of a dial indicator placed close to the crankshaft. Push the crankshaft to the rear and screw the top of the indicator until its face reads zero; push the crankshaft to the front and read its position which should range from 0.003 to 0.010 inch (0.076 to 0.254 mm). If the dial indicator is not available, it is possible to use feeler gauges to measure clearance. It is recommended to slacken the lower crankcase bolts gradually so that they can be peeled off by hands; all the center bolts in the lower crankcase should however be replaced with new ones whenever the crankcase is to be fastened again. Carefully unbolt and take out the lower crankcase without dropping bearing inserts and then lift the crankshaft ,where necessary with a little help. For installation, make sure that the engines block as well as crank shaft are clean and that they have been inspected. Place the engine block with crank; upwards, any original bearing inserts should also be removed and the bearing areas washed. Place new upper main bearing inserts on the engine block and position oil holes; place the lower main bearing inserts on the lower crankcase. By use of a clean cloth, wipe the outer faces of the crankshaft and the bearing inserts before positioning the crankshaft in place. When measuring the oil clearance of the main bearing it is advisable to use Plasti-gage and should not be interfered with while the process is going on. In case of incorrect clearance it is necessary to make sure that there was no debris during the measurement and check if the bearing inserts are worn-out and must be substituted. Upon removing of any Plastigage residue, place back the crankshaft, ensure that bearing surfaces are lubricated and finally place the lower crankcase, tighten and sequence bolts. Check the crankshaft end play again and try to turn it with little force on it. Last but not the least part is to fit the new rear main oil seal.

Related Chevrolet Malibu Parts

Browse by Year

2024 Crankshaft 2023 Crankshaft 2022 Crankshaft 2021 Crankshaft 2020 Crankshaft 2019 Crankshaft 2018 Crankshaft 2017 Crankshaft 2016 Crankshaft 2015 Crankshaft 2014 Crankshaft 2013 Crankshaft 2012 Crankshaft 2011 Crankshaft 2010 Crankshaft 2009 Crankshaft 2008 Crankshaft 2007 Crankshaft 2006 Crankshaft 2005 Crankshaft 2004 Crankshaft 2003 Crankshaft 2002 Crankshaft 2001 Crankshaft 2000 Crankshaft 1999 Crankshaft 1998 Crankshaft 1997 Crankshaft 1983 Crankshaft 1982 Crankshaft