My Garage

My Account

Cart

Genuine Chevrolet Malibu Flywheel

Clutch Flywheel- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

12 Flywheels found

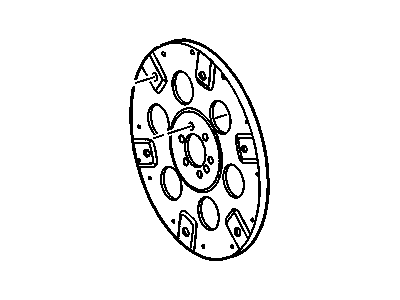

Chevrolet Malibu Automatic Transmission Flexible Plate Assembly

Part Number: 12647333$130.49 MSRP: $215.96You Save: $85.47 (40%)Ships in 1-3 Business DaysChevrolet Malibu Automatic Transmission Flexible Plate Assembly

Part Number: 12597026$63.26 MSRP: $100.90You Save: $37.64 (38%)Ships in 1-2 Business DaysChevrolet Malibu Engine Crankshaft Flywheel

Part Number: 24575970$84.70 MSRP: $170.81You Save: $86.11 (51%)Chevrolet Malibu Plate Assembly, A/Trns Flex

Part Number: 12686890$60.80 MSRP: $100.66You Save: $39.86 (40%)Ships in 1-3 Business DaysChevrolet Malibu Engine Crankshaft Flywheel

Part Number: 471529$140.65 MSRP: $166.69You Save: $26.04 (16%)Ships in 1-2 Business DaysChevrolet Malibu Automatic Transmission Flexible Plate Assembly

Part Number: 12686889$55.30 MSRP: $88.19You Save: $32.89 (38%)Ships in 1-3 Business DaysChevrolet Malibu Plate Assembly, Automatic Transmission Flexible

Part Number: 12638610$52.59 MSRP: $83.88You Save: $31.29 (38%)Chevrolet Malibu Automatic Transmission Flexible Plate Assembly

Part Number: 12686891$45.81 MSRP: $75.83You Save: $30.02 (40%)Ships in 1-3 Business DaysChevrolet Malibu Plate Assembly, Automatic Transmission Flexible

Part Number: 12637343$66.25 MSRP: $104.23You Save: $37.98 (37%)Ships in 1-3 Business Days

Chevrolet Malibu Flywheel

The Flywheel inside Chevrolet Malibu performs three fundamental duties by storing rotational power to generate constant engine torque and by connecting with the starter drive to activate the crankshaft during ignition startup and by giving the clutch disc sufficient friction to engage. There exist two main types of Flywheel as solid Flywheel and dual mass Flywheel (DMFs). Solid Flywheel operate with basic construction whereas dual mass Flywheel utilize springs in their damping unit to minimize engine vibrations for better vehicle comfort and performance shifts. The clutch contact surface wear eventually leads to the requirement of replacing the system part primarily affecting DMFs because these components cannot be refinished. The ring gear on the replacement unit can experience damage which might cause the driver to need a replacement unit. The Chevrolet Malibu replacement part stands as a critical component which ensures proper functioning of the engine alongside effective clutch performance in Chevrolet Malibu vehicles.

Each OEM Chevrolet Malibu Flywheel we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Chevrolet Malibu Flywheel Parts Questions & Experts Answers

- Q: How to remove and reinstall the Flywheel in four cylinder engine on Chevrolet Malibu?A:To remove the trans axle, first raise the vehicle and support it securely on jack stands, then if there is a leak, replace the front pump seal/O-ring. Make alignment marks on the drive plate and crankshaft using a center punch or paint to ensure correct alignment during reinstallation. Remove the bolts securing the drive plate to the crankshaft, using a screwdriver to wedge in the ring gear teeth if the crankshaft turns. Take off the drive plate, noting the orientation of any spacer present between it and the crankshaft. Inspect the drive plate for cracks and clean the mating surfaces of both the drive plate and crankshaft. If the crankshaft rear seal is leaking, replace it before reinstalling the drive plate. Position the drive plate against the crankshaft, reinstalling the spacer if it was originally present, and align the previously made marks. Some engines may have an alignment dowel or staggered bolt holes for correct installation. Apply thread locking compound to the bolt threads before installation. To prevent the drive plate from turning, wedge a screwdriver in the ring gear teeth and tighten the bolts in sequence to the specified torque, gradually working up to the final torque in three or four steps. The remaining steps for installation follow the reverse order of removal.

Related Chevrolet Malibu Parts

Browse by Year

2024 Flywheel 2023 Flywheel 2022 Flywheel 2021 Flywheel 2020 Flywheel 2019 Flywheel 2018 Flywheel 2017 Flywheel 2016 Flywheel 2015 Flywheel 2014 Flywheel 2013 Flywheel 2012 Flywheel 2011 Flywheel 2010 Flywheel 2009 Flywheel 2008 Flywheel 2007 Flywheel 2006 Flywheel 2005 Flywheel 2004 Flywheel 2003 Flywheel 2002 Flywheel 2001 Flywheel 2000 Flywheel 1999 Flywheel 1998 Flywheel 1997 Flywheel 1983 Flywheel 1982 Flywheel