My Garage

My Account

Cart

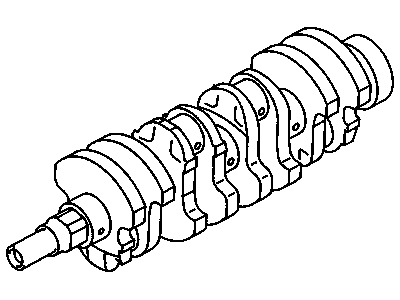

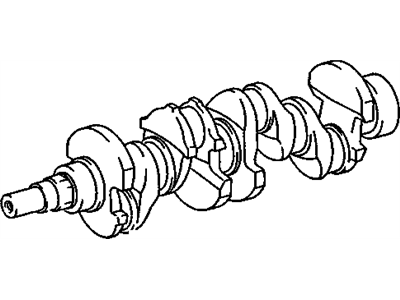

Genuine Chevrolet Nova Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Crankshafts found

Chevrolet Nova Crankshaft

Each OEM Chevrolet Nova Crankshaft we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Chevrolet Nova Crankshaft Parts Questions & Experts Answers

- Q: How to examine and check the crankpin, main journal surfaces, and crankshaft endplay on Chevrolet Nova?A:Examine the crankpin and main journal surfaces for scoring, scratches, or corrosion; if any are evident, the crankshaft will need professional regrinding. Use a micrometer to test each journal and crankpin at several points for ovality; if it exceeds 0.001 inch, regrinding is necessary. Undersize bearings are available to match the recommended regrind diameter, and typically, the parts salesperson will provide the correct bearings with the reconditioned crankshaft. After high mileage, main and connecting rod bearings may wear, leading to excessive running clearance, which can be checked using a proprietary product like 'Plastigage' after refitting the original bearings and caps and tightening the cap bolts to the specified torque settings. Always install new shell bearings after verifying the crankshaft journals and crankpins for ovality and confirming their diameters are standard or regrind sizes, and avoid turning the crankshaft while the 'Plastigage' is in place. Checking the connecting rod bearings follows a similar process, with the correct running clearance also specified. To check crankshaft endplay, force the crankshaft to the extreme front position and use a feeler gauge at the front end of the rear main bearing, ensuring the permissible clearance is adhered to.