My Garage

My Account

Cart

Genuine Oldsmobile Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

33 Crankshafts found

- Product Specifications

- Other Name: Crankshaft Asm ; Crankshaft, Engine; Crankshaft

Oldsmobile Engine Crankshaft

Part Number: 12555637$492.97 MSRP: $815.92You Save: $322.95 (40%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Crankshaft, Engine; Crankshaft

- Replaces: 12558256

Oldsmobile Engine Crankshaft

Part Number: 10243070$745.12 MSRP: $1233.22You Save: $488.10 (40%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Crankshaft, Engine; Crankshaft

- Replaced by: 12691722

Oldsmobile Crankshaft (Machining)

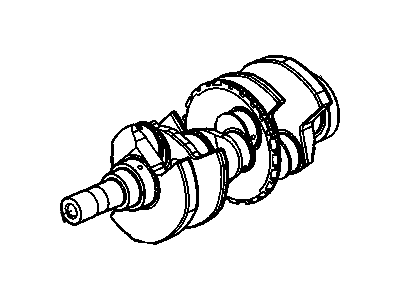

Part Number: 12561395$116.45 MSRP: $1523.71You Save: $1407.26 (93%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Crankshaft, (Machining) ; Crankshaft, Engine; Crankshaft

- Product Specifications

- Other Name: Crankshaft, Engine; Crankshaft

- Product Specifications

- Other Name: Crankshaft, Engine; Crankshaft

- Product Specifications

- Other Name: Crankshaft, (Machining); Crankshaft

- Product Specifications

- Other Name: Crankshaft Asm (.25 Mm Us) (Remanufacture) ; Crankshaft, Engine

- Replaces: 24575223

- Product Specifications

- Other Name: Crankshaft Asm; Crankshaft

- Replaces: 12556307

- Product Specifications

- Other Name: Crankshaf

- Product Specifications

- Other Name: Crankshaft, Engine

- Product Specifications

- Other Name: Crankshaft, Engine; Crankshaft

- Product Specifications

- Other Name: Crankshaft Asm; Crankshaft

- Product Specifications

- Other Name: Crankshaft,(Machining); Crankshaft

- Product Specifications

- Other Name: Crankshaft, (Machining) ; Crankshaft, (Mchg); Crankshaft

- Product Specifications

- Other Name: Crankshaft Asm; Crankshaft

- Product Specifications

- Other Name: Crankshaft, (Machining) ; Crankshaft, (Mchg); Crankshaft, Crankshaft Pulley

- Product Specifications

- Other Name: Crankshaft Asm; Crankshaft

- Product Specifications

- Other Name: Crankshaft, (Machining) ; Crankshaft, (Mchg); Crankshaft

| Page 1 of 2 |Next >

1-20 of 33 Results

Oldsmobile Crankshaft

Looking to acquire brand new parts? Consider exploring our extensive inventory of genuine Oldsmobile Crankshafts. Our offering of OEM Oldsmobile Crankshafts not only comes with competitive prices but also includes a manufacturer's warranty. For added convenience, we provide a hassle-free return policy and rapid delivery service. Shop with confidence on our platform.

Oldsmobile Crankshaft Parts Questions & Experts Answers

- Q: How to inspect and recondition crankshaft and connecting rod bearings in V8 engine on Oldsmobile Cutlass?A:Examine the crankpin and main journal surfaces for scoring, scratches, or corrosion; if any are evident, the crankshaft will need professional regrinding. Use a micrometer to test each journal and crankpin at several different points for ovality, and if it exceeds 0.001 inch, regrinding is necessary. Undersize bearings are available to match the recommended regrind diameter, typically supplied by your GM dealer with the reconditioned crankshaft. After high mileage, main and connecting rod bearings may wear, leading to excessive running clearance, which can be checked using a product like 'Plastigage' after refitting the original bearings and caps and tightening the cap bolts to the specified torque settings. Avoid correcting excessive running clearance by filing the caps; instead, fit new shell bearings after checking the crankshaft journals and crankpins for ovality and confirming their diameters. Checking connecting rod bearings follows a similar method, and it's advisable to check the running clearance of rod and main bearings even with new installations. The crankshaft endplay should be assessed by pushing the crankshaft to the extreme front position and using a feeler gauge at the front end of the rear main bearing. Measure the connecting rod side-clearance with a feeler gauge between the connecting rod caps, and if it falls outside the specified tolerance, replace the rod assembly.