My Garage

My Account

Cart

Genuine Oldsmobile Cutlass Brake Disc

Disc Rotor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

11 Brake Discs found

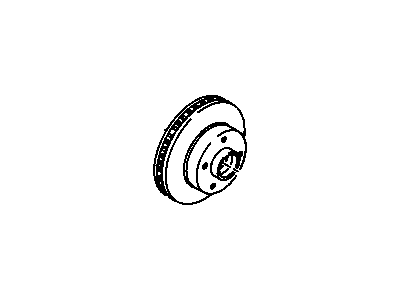

Oldsmobile Cutlass Front Brake Rotor

Part Number: 19171429$50.36 MSRP: $95.01You Save: $44.65 (47%)Ships in 1-3 Business Days

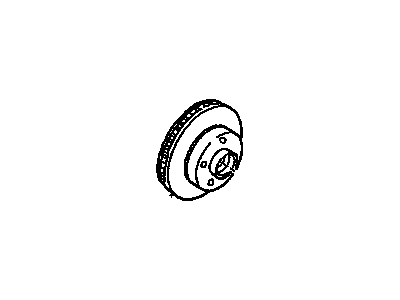

Oldsmobile Cutlass Brake Disc

The Brake Disc of the Oldsmobile Cutlass vehicles is one of the parts of the Disc brake system to offer the service of friction between brake pads to enable the vehicle to slow or stop. It is fixed to the axle or the hub and spins with the wheel, when the brake is applied then the hydraulic pressure is exerted on the caliper to squeeze the pads over the rotor. This mechanism makes for easier and better braking as we have seen that, disc brakes are slightly cooler than the drum brakes given that their construction is exposed to the immediate environment. For many years, Oldsmobile Cutlass automobiles have incorporated different types of Brake Discs, the solid type and the vented type. They are usually an iron cast which is a standard type for small modeled car while the vented types have fins to help in the releasing of heat and are common on the front. They are usually subjected to wear and tear which results in scoring, warping or excessive runout, which results in poor braking action if not maintained well. To get the premier out of Brake Discs it is advised to change them in pairs and stick to strict standards.

Each OEM Oldsmobile Cutlass Brake Disc we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Oldsmobile Cutlass Brake Disc Parts Questions & Experts Answers

- Q: How to check and inspect and Brake Disc and Brake Drum on Oldsmobile Cutlass?A:Whenever the disc Brake Pads are checked for wear, it is also necessary to look at the state or condition of the discs or rotors. Thus, ligth scoring or grooving are expected but deep grooves or severity erosion are not permitted. Some models have a specific channel, the so-called squeal groove, which should not be confused with damage. The existence of a vibration when the brake is applied has also been attributed to disc run out. To check for this, a dial gauge or feeler blades may be used between the disc and any fixed point. It was established that the disc should be turned at a slow rate in order not to exceed the runout of 0.004 inches. Thickness variations that are above the 0.0005 inches may also imply that the disc will vibrate during braking. Discs usually have wear limit and refinish thickness dimensions moulded on them. On the other hand, if a dealer fails to refinish a disc to certain standards of the set tolerance, a new disc has to be fitted. When a brake drum is pulled on a particular scheme for a lining inspection, it is necessary to look for cracks, 'scoring,' and out-of-round conditions. An out-of-round drum results in pulsations felt through the Brake Pedal during the application and the internal diameter has to be checked at various positions using an internal micrometer. Drums may be refinished internally; however, the wear and refinish sizes that may be cast into them must not be exceeded.