My Garage

My Account

Cart

Genuine Oldsmobile Flywheel

Clutch Flywheel- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

47 Flywheels found

Oldsmobile Automatic Transmission Flexible Plate Assembly

Part Number: 12647333$130.49 MSRP: $215.96You Save: $85.47 (40%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Plate Assembly, Automatic Transmission Flexible ; Plate, Engine Crankshaft; Disc, Drive Plate

- Replaces: 09126397, 12593689, 9126397

Oldsmobile Engine Crankshaft Flywheel

Part Number: 14088761$139.38 MSRP: $230.69You Save: $91.31 (40%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Flywheel, Engine Crankshaft; Drive Plate

Oldsmobile Engine Crankshaft Flywheel

Part Number: 12557586$372.76 MSRP: $536.04You Save: $163.28 (31%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Flywheel Asm. ; Flywheel, Engine Crankshaft; Flywheel

Oldsmobile Engine Crankshaft Flywheel

Part Number: 90537283$114.57 MSRP: $182.74You Save: $68.17 (38%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Flywheel Asm ; Flywheel, Engine Crankshaft; Flywheel

Oldsmobile Engine Crankshaft Flywheel

Part Number: 10118669$287.17 MSRP: $428.19You Save: $141.02 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Flywheel,Engine ; Flywheel, Engine Crankshaft; Flywheel

Oldsmobile Engine Crankshaft Flywheel

Part Number: 14088765$126.94 MSRP: $210.09You Save: $83.15 (40%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Flywheel, Engine Crankshaft; Drive Plate

Oldsmobile Automatic Transmission Flexplate

Part Number: 24502772$89.15 MSRP: $179.79You Save: $90.64 (51%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Flywheel Asm; Drive Plate

- Replaces: 24501753, 24502313

Oldsmobile Engine Crankshaft Flywheel

Part Number: 24575970$84.70 MSRP: $170.81You Save: $86.11 (51%)Product Specifications- Other Name: Flywheel Asm ; Flywheel, Engine Crankshaft; Drive Plate, Flywheel

- Replaces: 22533252, 12360472, 24571116

Oldsmobile Engine Crankshaft Flywheel

Part Number: 24501753$89.15 MSRP: $179.79You Save: $90.64 (51%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Flywheel Asm ; Flywheel, Engine Crankshaft; Drive Plate

- Replaced by: 24502772

- Product Specifications

- Other Name: Flywheel Asm; Flywheel

Oldsmobile Engine Crankshaft FLYWHEEL

Part Number: 3544671$97.14 MSRP: $136.33You Save: $39.19 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Flywheel Asm ; Flywheel, Engine Crankshaft; Drive Plate, Flywheel

Oldsmobile Flywheel Assembly (Includes Ring Gear)

Part Number: 24501986$20.57 MSRP: $182.37You Save: $161.80 (89%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Flywheel Asm (Includes Ring Gear)

- Product Specifications

- Other Name: Flywheel Asm; Flywheel

- Product Specifications

- Other Name: Flywheel Asm; Drive Plate, Flywheel

- Replaces: 10218513, 24576876, 24506847

Oldsmobile Engine Crankshaft Flywheel

Part Number: 12609155$52.23 MSRP: $82.19You Save: $29.96 (37%)Product Specifications- Other Name: Flywheel Asm ; Flywheel, Engine Crankshaft; Drive Plate, Flywheel

- Replaces: 24508110, 24505212

- Product Specifications

- Other Name: Plate,Automatic Transmission Flexible; Drive Plate

- Replaces: 24100152

- Product Specifications

- Other Name: Flywheel, Engine Crankshaft; Flywheel

- Product Specifications

- Other Name: Drive Plate

- Product Specifications

- Other Name: Flywheel, Engine Crankshaft

- Product Specifications

- Other Name: Flywheel Asm ; Flywheel, Engine Crankshaft; Drive Plate, Flywheel

- Replaces: 24506809

| Page 1 of 3 |Next >

1-20 of 47 Results

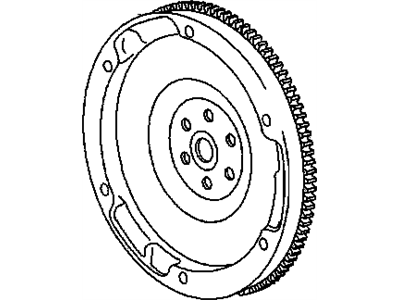

Oldsmobile Flywheel

Looking to acquire brand new parts? Consider exploring our extensive inventory of genuine Oldsmobile Flywheels. Our offering of OEM Oldsmobile Flywheels not only comes with competitive prices but also includes a manufacturer's warranty. For added convenience, we provide a hassle-free return policy and rapid delivery service. Shop with confidence on our platform.

Oldsmobile Flywheel Parts Questions & Experts Answers

- Q: How to properly remove and inspect the flywheel and crankshaft flange in V6 engine on Oldsmobile Cutlass?A:Remove the transmission and then take out the 6 bolts that attach the flywheel to the crankshaft flange, noting that the bolt holes are spaced unevenly to ensure the flex plate is installed correctly. Inspect the flex plate for cracks and replace it if necessary. Check the crankshaft flange and flex plate for any burrs or nicks, which should be removed with a mill file. Install the flex plate and torque the bolts to the proper specifications. To check flex plate run-out, mount a dial indicator on the engine block and measure at 3 attaching bosses, ensuring that crankshaft end play is held in one direction; run-out should not exceed .015 inches. If run-out exceeds this limit, tap the high side of the flex plate with a mallet or similar tool to correct it. If the issue persists, remove the flex plate and inspect the flywheel flange for burrs.