My Garage

My Account

Cart

Genuine Pontiac Universal Joint

U-Joint- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

8 Universal Joints found

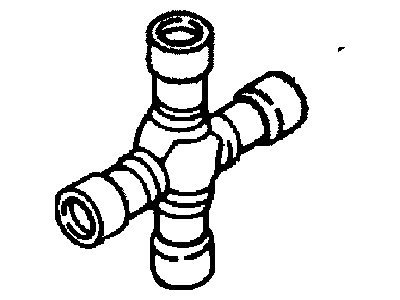

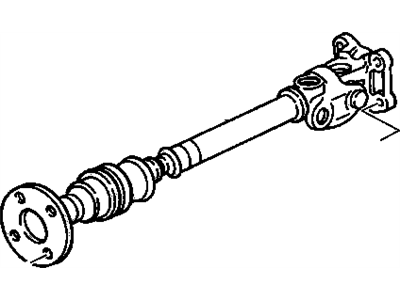

Pontiac Joint Kit, Front Axle Propeller Shaft Front Universal

Part Number: 23104840$51.58 MSRP: $88.98You Save: $37.40 (43%)Ships in 1-2 Business DaysProduct Specifications- Other Name: JOINT KIT, Propeller Shaft Universal Joint; Universal Joint

- Position: Front

- Replaces: 12471502, 12479126, 26042371

Pontiac Propeller Shaft Universal Joint Kit

Part Number: 91173316$56.84 MSRP: $114.62You Save: $57.78 (51%)Product Specifications- Other Name: JOINT KIT, Propeller Shaft Universal Joint; Universal Joint

- Replaces: 96069180

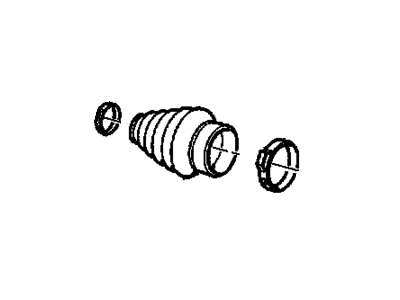

Pontiac Joint Kit,Rear Wheel Drive Shaft Outer Cv

Part Number: 92148957$27.34 MSRP: $655.50You Save: $628.16 (96%)Ships in 1-2 Business DaysProduct Specifications- Other Name: JOINT KIT, Rear Axle Universal Joint

- Position: Rear Outer

- Product Specifications

- Other Name: JOINT KIT, Propeller Shaft Universal Joint

- Position: Rear

- Product Specifications

- Other Name: JOINT KIT, Propeller Shaft Universal Joint; Universal Joint

- Position: Front

- Replaces: 14067678

- Product Specifications

- Other Name: JOINT KIT, Propeller Shaft Universal Joint; Universal Joint

- Product Specifications

- Other Name: JOINT KIT, Propeller Shaft Universal Joint

- Product Specifications

- Other Name: JOINT KIT, Rear Axle Universal Joint; Outer CV Joint, Outer Joint

- Position: Rear Outer

Pontiac Universal Joint

If you're searching for OEM Pontiac Universal Joints, look no further. Our website boasts an extensive inventory of genuine Pontiac Universal Joints, all available at competitive prices online. Every part we offer comes with a manufacturer's warranty. In addition, we provide a straightforward return policy and rapid delivery services, making your shopping experience a breeze.

Pontiac Universal Joint Parts Questions & Experts Answers

- Q: What steps should be followed to properly replace a universal joint on Pontiac Firebird?A:Before initiating the process, buy a service kit for your model universal joint and familiarise oneself with the process. Firstly, you should start by uninstalling the driveshaft, then securely mount the driveshaft on a workbench, on a vise. Ensure the universal joint is clamped on the vise using a socket with 1-1/8 inches diameter on one of the ear of the shaft yoke; the other end should be using the cross press tool, on the horizontal bearing cups which are opened; do not locked the driveshaft tubing. Full the bearing cup out of the yoke ear, shear the plastic retainer ring and if necessary use channel lock pliers to remove any stubborn cups. Again turn the driveshaft anticlockwise as much as required to force the other bearing cup out while shearing the plastic retainer. Pull out the cross from the yoke and take the production universal joint noting that these cannot be assembled again because there is no bearing retaining grooves. : If replacing the remaining universal joint on above described manner, press the bearing cups of the slip yoke as described above. For reassembly of gearbox, use all parts from the service kit, and scrap off all indications of plastic bearing retainers from the yoke grooves for suitable lodging of the bearing cups. Apply multi-purpose grease to lock the needle bearings during the assembly of the bearings cups, and washers so that they do not shift. Hand and place as far as possible the cups of the yoke and thereafter move the cross with the cups up and down to ensure proper contact before finally tightening the cups. When one snap-ring groove is out of the inside plane of the yoke you stop pressing and fix the snap-ring and keep on doing so till the other snap-ring can be put in and a hammer if necessary for moving the ends of the yoke ears. If done, fit the grease fitting lastly; then, re-fitting of the driveshaft is done.