My Garage

My Account

Cart

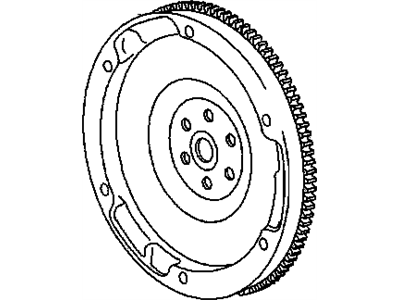

Genuine Pontiac Flywheel

Clutch Flywheel- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

72 Flywheels found

Pontiac Automatic Transmission Flexible Plate Assembly

Part Number: 12654640$132.41 MSRP: $226.41You Save: $94.00 (42%)Product Specifications- Other Name: Plate Assembly, Automatic Transmission Flexible ; Plate, Engine Crankshaft; Drive Plate, Flywheel

- Replaces: 12553054, 12602448, 12606620, 12637677, 12563136, 12580709

Pontiac Automatic Transmission Flexible Plate Assembly

Part Number: 12647333$130.49 MSRP: $215.96You Save: $85.47 (40%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Plate Assembly, Automatic Transmission Flexible ; Plate, Engine Crankshaft; Disc, Drive Plate

- Replaces: 09126397, 12593689, 9126397

Pontiac Automatic Transmission Flexible Plate Assembly

Part Number: 12597026$63.26 MSRP: $100.90You Save: $37.64 (38%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Plate Assembly, Automatic Transmission Flexible ; Plate, Engine Crankshaft; Drive Plate

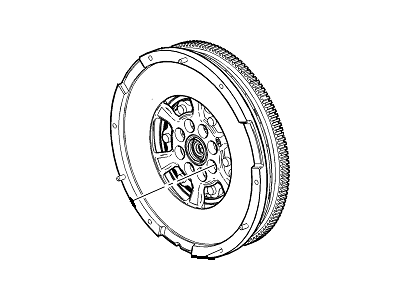

Pontiac Engine Crankshaft Flywheel

Part Number: 90537283$114.57 MSRP: $182.74You Save: $68.17 (38%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Flywheel Asm ; Flywheel, Engine Crankshaft; Flywheel

Pontiac Engine Crankshaft Flywheel

Part Number: 10118669$287.17 MSRP: $428.19You Save: $141.02 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Flywheel,Engine ; Flywheel, Engine Crankshaft; Flywheel

Pontiac Engine Crankshaft Flywheel

Part Number: 14088765$126.94 MSRP: $210.09You Save: $83.15 (40%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Flywheel, Engine Crankshaft; Drive Plate

Pontiac Flywheel Assembly

Part Number: 14097667$90.83 MSRP: $183.15You Save: $92.32 (51%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Flywheel Asm; Drive Plate

- Replaces: 14100557

Pontiac Automatic Transmission Flexplate

Part Number: 24502772$89.15 MSRP: $179.79You Save: $90.64 (51%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Flywheel Asm; Drive Plate

- Replaces: 24501753, 24502313

- Product Specifications

- Other Name: Flywheel Asm ; Flywheel, Engine Crankshaft; Drive Plate, Flywheel

- Replaces: 22533252, 12360472, 24571116

Pontiac Engine Crankshaft Flywheel

Part Number: 24501753$89.15 MSRP: $179.79You Save: $90.64 (51%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Flywheel Asm ; Flywheel, Engine Crankshaft; Drive Plate

- Replaced by: 24502772

Pontiac Automatic Transmission Flexible Plate Assembly

Part Number: 96488000$42.52 MSRP: $67.81You Save: $25.29 (38%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Plate Asm,Automatic Transmission Flexible ; Plate, Engine Crankshaft; Drive Plate

Pontiac Flywheel Assembly

Part Number: 25198268$152.19 MSRP: $251.89You Save: $99.70 (40%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Flywheel Asm; Flywheel

- Replaces: 96184353

Pontiac Engine Crankshaft Flywheel

Part Number: 471529$140.65 MSRP: $166.69You Save: $26.04 (16%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Flywheel, Engine Crankshaft; Drive Plate

Pontiac Clutch Flywheel (W/M40)

Part Number: 90236309$178.53 MSRP: $278.39You Save: $99.86 (36%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Flywheel,W/Ring Gear(W/M40); Flywheel

Pontiac Engine Crankshaft Flywheel

Part Number: 12584343$442.25 MSRP: $698.99You Save: $256.74 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Flywheel Asm ; Flywheel, Engine Crankshaft; Flywheel

- Product Specifications

- Other Name: Flywheel Asm; Flywheel

Pontiac Flywheel Assembly, (W/ Clutch Pressure Plate)

Part Number: 92161753$532.19 MSRP: $880.44You Save: $348.25 (40%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Flywheel

- Replaces: 92067954, 92065668

- Product Specifications

- Other Name: Flywheel Asm; Drive Plate, Flywheel

- Replaces: 10218513, 24576876, 24506847

Pontiac Automatic Transmission Flexible Plate Assembly

Part Number: 12589349$74.13 MSRP: $116.65You Save: $42.52 (37%)Product Specifications- Other Name: Plate Assembly, Automatic Transmission Flexible ; Plate, Engine Crankshaft; Drive Plate

- Product Specifications

- Other Name: Flywheel, Engine Crankshaft; Drive Plate

| Page 1 of 4 |Next >

1-20 of 72 Results

Pontiac Flywheel

If you're searching for OEM Pontiac Flywheels, look no further. Our website boasts an extensive inventory of genuine Pontiac Flywheels, all available at competitive prices online. Every part we offer comes with a manufacturer's warranty. In addition, we provide a straightforward return policy and rapid delivery services, making your shopping experience a breeze.

Pontiac Flywheel Parts Questions & Experts Answers

- Q: How to remove and install the Flywheel in four cylinder engine on Pontiac Fiero?A:This is a one-piece oil seal, which is conveniently designed to be replaced without having to ad-remove the oil pan or crankshaft. First of all, it is necessary to unbolt the trans axle which must be done while adhering to all the notes on the procedure. If the vehicle has manually trans axle then the pressure plate and clutch disk should be removed. What comes next is the elimination of the flywheel or the drive plate retaining bolts and pop it off from the crankshaft. Remove the rear main oil seal with a screwdriver or pry bar by gently prying it out of the block. Thoroughly wash the crankshaft-to-seal and block mating surface with solvent. Before installing a new seal, a thin layer of engine oil must be spread over the exterior of the seal, and it is fixed firmly into the block using the fingertips. Replace the flywheel or the drive plate, after having the bolts tightly fastened to the recommended torque level. For the manual trans axle vehicles, replace the clutch disc and the pressure plate and then fit the trans axle.

- Q: How to properly remove and reinstall a flywheel in 2.5L four cylinder engine on Pontiac Grand Prix?A:Raise the vehicle and support it securely on jackstands, then remove the transaxle. If there's a leak, it's an ideal time to replace the front pump seal and O-ring for automatic transaxles. In the absence of a dowel pin, mark the driveplate and crankshaft to ensure correct alignment during reinstallation, as most driveplates have locating dowels. Remove the bolts securing the driveplate to the crankshaft, using a large screwdriver to prevent the driveplate from turning. If the crankshaft turns, wedge a screwdriver through the openings in the driveplate, and support the driveplate while removing the last bolt. After removing the driveplate, clean it to eliminate grease and oil, inspecting for cracks and damaged ring gear teeth, and check for warpage using a straightedge. Clean and inspect the mating surfaces of the driveplate and crankshaft, replacing the crankshaft rear seal if it's leaking before reinstalling the driveplate. Position the driveplate against the crankshaft, aligning the dowel or marks made during removal, and apply thread locking compound to the bolt threads before installation. Prevent the driveplate from turning while tightening the bolts to the specified torque, and complete the installation by reversing the removal procedure.

- Q: How to remove and install the transaxle and flywheel in four cylinder engine on Pontiac G6?A:To have the transaxle replaced, the vehicle needs to be lifted to a certain height using the hydraulic jack and supported using the jackstands afterwards the transaxle has to be removed. In particular, if there is a leakage detected, one should replace the front pump seal/O-ring at the time. Subsequently, the bolts which fasten the driveplate to the crankshaft must be undone carefully because the heads of these bolts are thin; to ensure that they sit properly in the socket for optimum grip, the edge may need grinding. If the crankshaft turns, take a flat-head screwdriver, and by placing it between the teeth of the ring gear, turn it to jam the driveplate. After that, it is necessary to remove the driveplate from the crankshaft and to get the spacer out if it was used. For installation, remove all grease and oil from the driveplate and be sure to check for any cracks or other signs of damage, likewise, check the ring gear to be ensure that none of the teeth is cracked or broken. Place the driveplate horizontally and run a straight edge across it to be sure it has not developed a twist. Check/clean the mating surfaces of the driveplate and crankshaft, a leaking rear crankshaft seal , before reinstalling of the driveplate. Align the driveplate against the crankshaft and before tightening the bolt apply thread locking compound on the threads of the bolt. While tightening the bolts, use a screwdriver in the ring gear teeth so that the driveplate does not turn. Tighten to the recommended torque measurements. Last but not least, do the reversing of the removal operation to fully install the software.

Related Pontiac Parts

Browse by Model

6000 Flywheel Aztek Flywheel Bonneville Flywheel Fiero Flywheel Firebird Flywheel G3 Flywheel G5 Flywheel G6 Flywheel G8 Flywheel GTO Flywheel Grand Am Flywheel Grand Prix Flywheel J2000 Flywheel LeMans Flywheel Montana Flywheel Parisienne Flywheel Phoenix Flywheel Pursuit Flywheel Safari Flywheel Solstice Flywheel Sunbird Flywheel Sunfire Flywheel Sunrunner Flywheel Torrent Flywheel Trans Sport Flywheel Vibe Flywheel