My Garage

My Account

Cart

Genuine Pontiac Drive Belt

Serpentine Belt- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

94 Drive Belts found

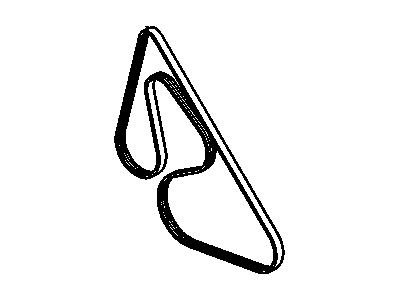

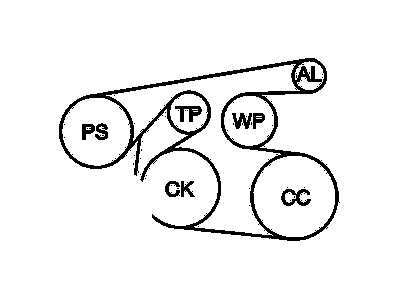

Pontiac Belt, Fan & Water Pump & A/C Compressor & Generator & P/S P

Part Number: 12576750$62.19 MSRP: $111.58You Save: $49.39 (45%)Ships in 1-2 Business DaysProduct Specifications- Other Name: BELT, Drive; Serpentine Belt

- Replaces: 12563072, 12596340, 12574093

Pontiac Belt,Generator & A/C Compressor

Part Number: 88984195$15.08 MSRP: $26.33You Save: $11.25 (43%)Ships in 1-2 Business DaysProduct Specifications- Other Name: BELT, Drive

- Replaces: 24573205, 24573206, 12569539, 24576787, 24575537, 24575751

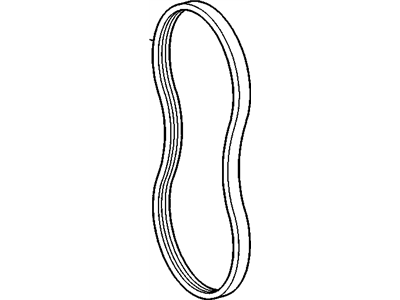

Pontiac Belt,Water Pump & A/C Compressor & Generator & P/S Pump

Part Number: 88971576$35.97 MSRP: $64.50You Save: $28.53 (45%)Ships in 1-2 Business DaysProduct Specifications- Other Name: BELT, Drive; Serpentine Belt

Pontiac Belt, Generator & A/C Compressor

Part Number: 12634319$21.81 MSRP: $41.15You Save: $19.34 (47%)Ships in 1-3 Business DaysProduct Specifications- Other Name: BELT, Drive; Serpentine Belt

- Replaces: 24435940, 12618358, 24466972

Pontiac Belt,Water Pump

Part Number: 12588412$17.91 MSRP: $29.47You Save: $11.56 (40%)Ships in 1-2 Business DaysProduct Specifications- Other Name: BELT, Drive

- Replaces: 03545016, 12570499, 12555957, 3545016

Pontiac Belt, Water Pump & A/C Compressor & Generator & P/S Pump

Part Number: 12588408$33.11 MSRP: $56.60You Save: $23.49 (42%)Ships in 1-2 Business DaysProduct Specifications- Other Name: BELT, Drive; Serpentine Belt

- Replaces: 12569376, 24508562

Pontiac Belt,Water Pump & A/C Compressor & Supercharge

Part Number: 88986818$30.61 MSRP: $70.38You Save: $39.77 (57%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Serpentine Belt; Belt, Drive Belt

- Replaces: 24503551

- Product Specifications

- Other Name: BELT

- Product Specifications

- Other Name: BELT, P/S

- Product Specifications

- Other Name: Alternator Belt

- Replaces: 24504257

- Product Specifications

- Other Name: BELT, Drive; Alternator Belt, Belt

- Product Specifications

- Other Name: BELT, Drive; Power Steering Belt

- Product Specifications

- Other Name: Belt

- Product Specifications

- Other Name: BELT, Drive; A.I.R. Belt, A.I.R. Pump Belt, AC Belt, Belt

- Product Specifications

- Other Name: BELT, A/C

Pontiac Belt, Generator

Part Number: 12634322$16.70 MSRP: $30.36You Save: $13.66 (45%)Ships in 1-2 Business DaysProduct Specifications- Other Name: BELT, Drive; Serpentine Belt

- Replaces: 24466976, 24435953

Pontiac Belt, Water Pump & A/C Compressor & Generator & P/S Pump

Part Number: 12578869$43.40 MSRP: $77.87You Save: $34.47 (45%)Ships in 1-3 Business DaysProduct Specifications- Other Name: BELT, Drive; Serpentine Belt

Pontiac Belt,Generator & A/C Compressor

Part Number: 12639468$20.77 MSRP: $37.28You Save: $16.51 (45%)Product Specifications- Other Name: BELT, Drive; Serpentine Belt

- Replaces: 12600851

- Product Specifications

- Other Name: BELT, Drive; Serpentine Belt

- Replaces: 10041197

- Product Specifications

- Other Name: BELT, Drive; Power Steering Belt

| Page 1 of 5 |Next >

1-20 of 94 Results

Pontiac Drive Belt

If you're searching for OEM Pontiac Drive Belts, look no further. Our website boasts an extensive inventory of genuine Pontiac Drive Belts, all available at competitive prices online. Every part we offer comes with a manufacturer's warranty. In addition, we provide a straightforward return policy and rapid delivery services, making your shopping experience a breeze.

Pontiac Drive Belt Parts Questions & Experts Answers

- Q: What is the method for measuring and adjusting Drive Belt tension on Pontiac Fiero?A:Check the tension of each belt by pushing on it at a distance halfway between the pulleys. Push firmly with your thumb and measure this deflection with a ruler. The belt should deflect 114-inch if the distance from pulley center to pulley center is between 7 and 11 inches. The belt should deflect 112:inch if the distance from pulley center to pulley center is between 12 and 16 inches. Another, more precise method of measuring and adjusting belt deflection is accomplished with special belt tension tools which are available from General Motors (J-23600-B or BT 33-95-ACBN). These tools measure the amount of force required to deflect a belt a specified distance. To adjust belt tension, loosen the pivot bolt(s) securing the belt-driven component to the engine block and the retaining nut or bolt securing the component to the slotted adjustment bracket. Use a levering device, such as a large screwdriver or pry bar, to pivot the component until the specified tension is achieved. Be careful not to damage either the component or the engine. Tighten the retaining nut or bolt securing the component to its slotted adjustment bracket snug enough to hold it. Check the belt tension again. Adjust as necessary. Tighten the component securely. If inspection reveals that a belt must be replaced, loosen the pivot bolt of the appropriate accessory (alternator, air conditioning compressor, etc.), slip the old belt off the crankshaft pulley and accessory pulley, then lift it out. Before installing the new belt, make sure it's the same width and length as the old one. Once the new belt is in place, tighten and adjust it just like you would a used belt.

Related Pontiac Parts

Browse by Model

6000 Drive Belt Aztek Drive Belt Bonneville Drive Belt Fiero Drive Belt Firebird Drive Belt G3 Drive Belt G5 Drive Belt G6 Drive Belt G8 Drive Belt GTO Drive Belt Grand Am Drive Belt Grand Prix Drive Belt J2000 Drive Belt Montana Drive Belt Parisienne Drive Belt Phoenix Drive Belt Pursuit Drive Belt Solstice Drive Belt Sunbird Drive Belt Sunfire Drive Belt Torrent Drive Belt Trans Sport Drive Belt Vibe Drive Belt