My Garage

My Account

Cart

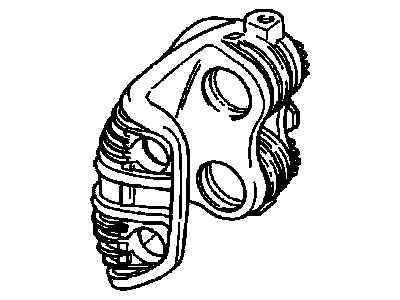

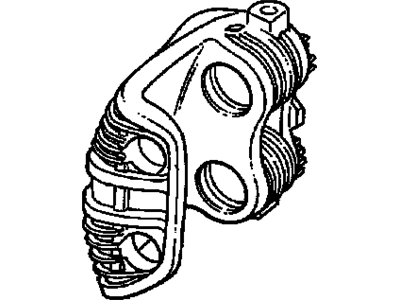

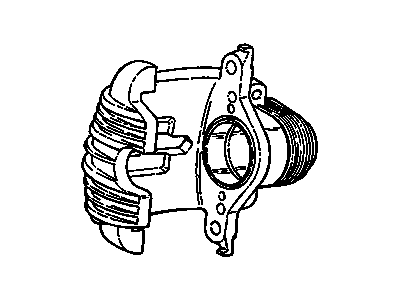

Genuine Pontiac Firebird Brake Calipers

Caliper- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

22 Brake Calipers found

| Page 1 of 2 |Next >

1-20 of 22 Results

Pontiac Firebird Brake Calipers

The Brake Calipers is an important component of the braking system of Pontiac Firebird vehicles, it utilises hydraulic pressure provided by the master cylinder to generate the mechanical force required to apply the brake pads against the rotors to obtain deceleration or stopping mechanisms of the car. Pontiac Firebird models utilize two primary types of Brake Caliperss: There are two types of bridges namely the fixed and the floating. In fixed caliper brake there are numerous pistons applied on both side of the rotor apply constant pressure while floating type caliper have pistons on only one side and slide to apply pressure this can be problematic in regard to uneven wear of pads if not maintained properly. Some of the known changes that has happened in the years pertaining to the Pontiac Firebird Brake Caliperss are the choices between the standard OE and the high performance kind. The performance calipers improve the braking performance and looks of wheels for normal vehicles and for racing vehicles as well. The changes are found in the type of material used, the pistons and the other structure and build of the calipers which determine their usage and efficiency depending on the driving conditions.

Each OEM Pontiac Firebird Brake Calipers we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Pontiac Firebird Brake Calipers Parts Questions & Experts Answers

- Q: What steps should be taken before beginning the Brake Calipers overhaul procedure on Pontiac Firebird?A:Ensure that before you undertake this procedure you buy a brake caliper overhaul kit that applies to your car. For single piston caliper of automobile, begin by partially undoing the caliper and Brake Pads. Using brake fluid clean the exterior of the brake caliper gently and not to use gasoline kerosene or the like cleaning solvent thereafter place the brake caliper on a clean working bench. Place a piece of wood or a shop rag in the caliper to deaden the shifting of piston, then compress the caliper with the air and ease the piston out to prevent having the piston snapping off. Slide the dust boot out of the caliper bore, and use wooden or plastic material to remove the piston seal from slot. Twist the caliper bleeder valve and then dispose the sleeves, bushings and all rubber components. Dip the rest of the parts in brake fluid and let them sit for a few minutes, and then invert the parts in order to spill out as much brake fluid as possible. Analyse the piston for nicks, burrs or loss of plating and the caliper bore for similar conditions but only providing light surface honing with crocus cloth for mild corrosion. Anyone of the mounting bolts which has sign of corrosion or has been damaged in any way should also be rejected. On assembly it is important to apply clean brake fluid on the piston bores and the seal should then be inserted in the caliper bore groove as depicted below; Wipe off the piston and assemble a boot having the fold toward the open end and with the piston squarely placed in the caliper bore apply pressure to help the piston settle on the bottom. Place the dust boot in the caliper counter bore and Msh with the drift to properly set into place the dust boot under the caliper face and then fit the bleeder value. The installation is carried out in the reverse of the removal process using new copper gaskets at the brake hose connection as well as bleeding of the system. In the case of a dual-piston caliper, the procedure is slightly different, and while it is relatively safe, be careful, as the bulk of the material here is aluminum, and it can easily be scratched. When using compressed air to remove the pistons, if they do not come out at the same time, and remove the boot from the unloaded cylinder and reinsert the piston to seal the cylinder and use the spacer to pry out the other piston. Repeat all the above mentioned procedures for the pistons, and bore checks, and use only fingers to install the piston boots into the caliper bores.

Related Pontiac Firebird Parts

Browse by Year

2002 Brake Calipers 2001 Brake Calipers 2000 Brake Calipers 1999 Brake Calipers 1998 Brake Calipers 1997 Brake Calipers 1996 Brake Calipers 1995 Brake Calipers 1994 Brake Calipers 1993 Brake Calipers 1992 Brake Calipers 1991 Brake Calipers 1990 Brake Calipers 1989 Brake Calipers 1988 Brake Calipers 1987 Brake Calipers 1986 Brake Calipers 1985 Brake Calipers 1984 Brake Calipers 1983 Brake Calipers 1982 Brake Calipers