My Garage

My Account

Cart

Genuine Pontiac Firebird Brake Disc

Disc Rotor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

7 Brake Discs found

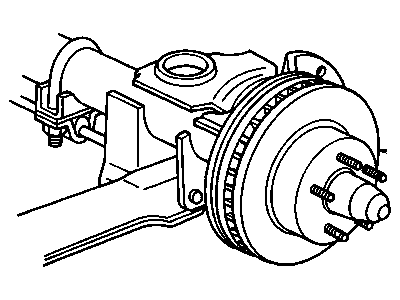

Pontiac Firebird Rear Disc Brake Machining Assembly

Part Number: 14026865$61.78 MSRP: $112.33You Save: $50.55 (45%)Pontiac Firebird Rear Brake Rotor Assembly

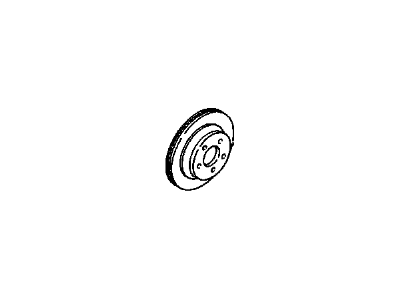

Part Number: 19174935$45.20 MSRP: $85.28You Save: $40.08 (47%)Ships in 1-3 Business Days

Pontiac Firebird Brake Disc

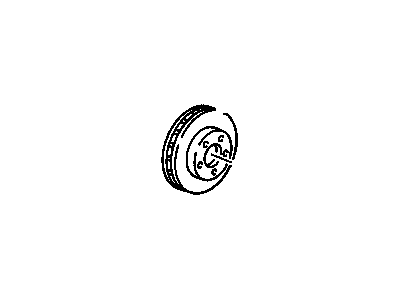

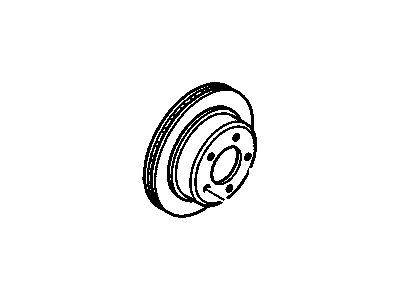

The Brake Disc of Pontiac Firebird vehicles is among the disc braking system, which offers the requisite friction for the brake pads to halt or slowdown the vehicle. Fitted to the axle or hub, wherein it turns together with the wheel, when brakes are applied, hydraulic pressure is exerted to squeeze the caliper and bring the pads into touch with the rotor. This design enables cooling and in particular in the vented rotos that incorporate cooling flutes, commonly used in high-performance axles. It is worth to note that different types of Brake Discs have been used in the years of Pontiac Firebird models, namely, solid and vented. Conventional rotors are predominantly utilised on non- performance or economy car applications while the vented rotors help to provide better cooling. This is important because rotors can be damaged by factors such as scoring, warping as well as excessive runout which will affect the braking system. Thus, it could be established that, In Got Pontiac Firebird Vehicles it is critically important that Brake Discs should be inspected and replaced from time to time.

Each OEM Pontiac Firebird Brake Disc we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Pontiac Firebird Brake Disc Parts Questions & Experts Answers

- Q: How to properly remove and inspect the front brake disc on Pontiac Firebird?A:Raise the vehicle and place it securely on jackstands, then remove the appropriate wheel and tire. Next, remove the brake caliper assembly, ensuring not to disconnect the brake hose on front disc brakes; after removing the caliper mounting bolts, hang the caliper out of the way using a piece of wire, avoiding any strain on the brake hose to prevent damage. Inspect the Brake Disc surfaces for light scoring or grooving, which is normal, but be cautious of deep grooves or severe erosion, especially if pulsating has been noticed during brake application, as this may indicate disc run out. Attach a dial indicator to the caliper mounting bracket, turn the Brake Disc, and note the amount of run out, checking both inboard and outboard surfaces; if the run out exceeds the maximum allowable, the Brake Disc must be removed and taken to an automotive machine shop for resurfacing. Measure the thickness of the Brake Disc with a micrometer, and if it is less than the minimum specified, replace it with a new one, also measuring the disc thickness at several points to check for variations; any variation over 0.0005-inch may cause pedal pulsations during brake application, and if this condition exists while the disc thickness is above the minimum, the Brake Disc can be removed for resurfacing. For the removal and installation of the front Brake Disc, check and repack the wheel bearings, and note that the Brake Disc on rear wheel disc brake models can be pulled off after the caliper is removed.

Related Pontiac Firebird Parts

Browse by Year

2002 Brake Disc 2001 Brake Disc 2000 Brake Disc 1999 Brake Disc 1998 Brake Disc 1997 Brake Disc 1996 Brake Disc 1995 Brake Disc 1994 Brake Disc 1993 Brake Disc 1992 Brake Disc 1991 Brake Disc 1990 Brake Disc 1989 Brake Disc 1988 Brake Disc 1987 Brake Disc 1986 Brake Disc 1985 Brake Disc 1984 Brake Disc 1983 Brake Disc 1982 Brake Disc