My Garage

My Account

Cart

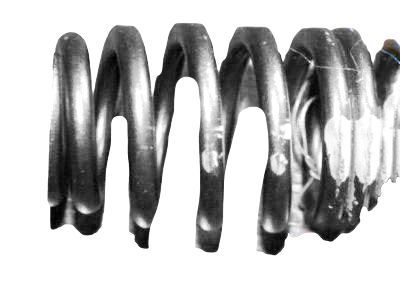

Genuine Pontiac Rocker Shaft Spring Kit

Rocker Shaft Spring Set- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

45 Rocker Shaft Spring Kits found

- Product Specifications

- Other Name: SPRING, Engine Valve; Valve Spring

Pontiac Bolt, Heavy Hx Acorn Flange Head

Part Number: 11588728$4.46 MSRP: $7.02You Save: $2.56 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: BOLT, Engine Front Cover

- Replaces: 11519171

Pontiac Spring Assembly, Valve

Part Number: 12600774$8.80 MSRP: $11.45You Save: $2.65 (24%)Ships in 1-2 Business DaysProduct Specifications- Other Name: SPRING, Engine Valve; Valve Spring

- Replaces: 12595094

Pontiac Spring, Valve (W/ Dampener)

Part Number: 3911068$9.01 MSRP: $14.18You Save: $5.17 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: SPRING, Engine Valve; Valve Spring

- Replaced by: 94666580

- Product Specifications

- Other Name: Valve Spring

- Product Specifications

- Other Name: SPRING, Engine Valve; Valve Spring

- Product Specifications

- Other Name: SPRING, Engine Valve; Valve Spring

- Product Specifications

- Other Name: SPRING, Engine Valve; Valve Spring

- Product Specifications

- Other Name: SPRING, Engine Valve; Valve Spring

- Product Specifications

- Other Name: SPRING, Engine Valve; Valve Spring

Pontiac Spring,Valve

Part Number: 90537032$4.88 MSRP: $8.08You Save: $3.20 (40%)Ships in 1-3 Business DaysProduct Specifications- Other Name: SPRING, Engine Valve; Valve Spring

Pontiac Spring,Valve

Part Number: 55567950$11.45 MSRP: $18.02You Save: $6.57 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: SPRING, Engine Valve; Valve Spring

- Replaces: 55354287

Pontiac Spring,Valve

Part Number: 12565199$1.67 MSRP: $2.78You Save: $1.11 (40%)Ships in 1-3 Business DaysProduct Specifications- Other Name: SPRING, Engine Valve; Valve Spring

Pontiac Spring,Valve

Part Number: 96353128$3.83 MSRP: $6.33You Save: $2.50 (40%)Ships in 1-2 Business DaysProduct Specifications- Other Name: SPRING, Engine Valve; Valve Spring

Pontiac Spring,Valve

Part Number: 88972332$1.76 MSRP: $10.76You Save: $9.00 (84%)Ships in 1-2 Business DaysProduct Specifications- Other Name: SPRING, Engine Valve; Valve Spring

Pontiac Spring Kit,Valve (W/Cap)

Part Number: 19257200$8.96 MSRP: $14.82You Save: $5.86 (40%)Ships in 1-3 Business DaysProduct Specifications- Other Name: SPRING KIT, Engine Valve; Valve Spring

- Replaces: 12537174

Pontiac Spring, Valve Feder, Ventil

Part Number: 90265608$4.17 MSRP: $6.65You Save: $2.48 (38%)Ships in 1-3 Business DaysProduct Specifications- Other Name: SPRING, Engine Valve; Valve Spring

- Replaces: 90180310

Pontiac Spring Assembly, Vlv

Part Number: 94666580$12.60 MSRP: $14.18You Save: $1.58 (12%)Ships in 1-3 Business DaysProduct Specifications- Replaces: 3911068, 03911068

- Product Specifications

- Other Name: SPRING, Engine Valve; Valve Spring

- Product Specifications

- Other Name: SPRING, Engine Valve; Valve Spring

| Page 1 of 3 |Next >

1-20 of 45 Results

Pontiac Rocker Shaft Spring Kit

If you're searching for OEM Pontiac Rocker Shaft Spring Kits, look no further. Our website boasts an extensive inventory of genuine Pontiac Rocker Shaft Spring Kits, all available at competitive prices online. Every part we offer comes with a manufacturer's warranty. In addition, we provide a straightforward return policy and rapid delivery services, making your shopping experience a breeze.

Pontiac Rocker Shaft Spring Kit Parts Questions & Experts Answers

- Q: Can broken Rocker Shaft Spring Kit and Valve Stem Oil Seal be replaced without removing the cylinder head in 2.5L four cylinder engine on Pontiac Grand Prix?A:Valve springs and valve stem seals that are broken or defective do not have to be replaced with the cylinder head removed, and the job requires generally two special tools and a compressed air line. In the absence of compressed air, a piece of nylon rope can be utilised in order to prevent the valves from falling into the cylinder. Start with unscrewing the valve cover along with the spark plug from the cylinder concerned, if it is an individual cylinder valve stem seal replacement, or all spark plugs if you're replacing all the valve stem seals. Rotate the crankshaft until the piston is at TDC on the compression stroke, although the operation is done cylinder by cylinder in the firing sequence. Insert a threaded adaptor into the spark plug hole while connecting an air compressor to the other terminal of the air hose. The bolt holding the defective valve, pivot ball, and rocker arm should be unscrewed, and the pushrod ought to be withdrawn. Use compressed air on the cylinder, thereby restraining the valves with the barrel pressure. Should air pressure not deliver, a valve job might be in order. Otherwise, place the piston slightly before the top dead centre, push a nylon rope into the combustion chamber and turn the crankshaft until it meets some opposition. Employ shop rags so that the parts do not drop into the engine then compress the valve spring using a valve spring compressor and pull the keepers. First you should take off the spring retainer and the valve spring afterward the valve guide seal. If the pressure keeps the valve closed, the valve face or seat may get ruined, and thereby one has to remove the cylinder head. Loosen a rubber band or some tape around the valve stem so that it does not fall off then deflate the tire. Visually check for some degree of wear on the valve stem and then check that it rotates with ease in the guide. Admit air pressure in order to reseat the valve, coat the valve stem with engine oil and put on a new valve guide slug. Place the spring over the valve, put the spring retainer in place, push the spring down and put the keepers in place and grease them if required. Pull the air hose off, take the adapter out and replace the rocker arms and the push rods, spark plugs and the wires. Last of all, fit back the valve cover, if required tighten the bolts, start the engine and do look out for any dripping of oil or any strange noise.

Related Pontiac Parts

Browse by Model

6000 Rocker Shaft Spring Kit Aztek Rocker Shaft Spring Kit Bonneville Rocker Shaft Spring Kit Fiero Rocker Shaft Spring Kit Firebird Rocker Shaft Spring Kit G3 Rocker Shaft Spring Kit G5 Rocker Shaft Spring Kit G6 Rocker Shaft Spring Kit G8 Rocker Shaft Spring Kit Grand Am Rocker Shaft Spring Kit Grand Prix Rocker Shaft Spring Kit LeMans Rocker Shaft Spring Kit Montana Rocker Shaft Spring Kit Parisienne Rocker Shaft Spring Kit Phoenix Rocker Shaft Spring Kit Pursuit Rocker Shaft Spring Kit Safari Rocker Shaft Spring Kit Solstice Rocker Shaft Spring Kit Sunbird Rocker Shaft Spring Kit Sunfire Rocker Shaft Spring Kit Sunrunner Rocker Shaft Spring Kit Torrent Rocker Shaft Spring Kit Trans Sport Rocker Shaft Spring Kit Vibe Rocker Shaft Spring Kit