My Garage

My Account

Cart

Genuine Cadillac Escalade Drive Belt

Serpentine Belt- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

29 Drive Belts found

Cadillac Escalade Belt Kit, A/C Compressor

Part Number: 12658178$58.00 MSRP: $96.22You Save: $38.22 (40%)Cadillac Escalade Belt,Fan & Water Pump & A/C Compressor & Generator & P/S Pump

Part Number: 12564763$26.89 MSRP: $62.37You Save: $35.48 (57%)Cadillac Escalade Belt, Water Pump & A/C Compressor & Generator & P/S Pump

Part Number: 12636138$38.67 MSRP: $72.97You Save: $34.30 (48%)Ships in 1-3 Business DaysCadillac Escalade Belt, Fan

Part Number: 12637200$56.33 MSRP: $102.42You Save: $46.09 (45%)Ships in 1-3 Business DaysCadillac Escalade Belt, Water Pump & Generator

Part Number: 12626076$23.49 MSRP: $42.14You Save: $18.65 (45%)Ships in 1-2 Business DaysCadillac Escalade Belt, Fan & Water Pump & Generator & P/S Pump

Part Number: 12637204$50.06 MSRP: $89.82You Save: $39.76 (45%)Ships in 1-3 Business DaysCadillac Escalade Belt Kit,A/C Compressor

Part Number: 19210691$42.64 MSRP: $74.63You Save: $31.99 (43%)Ships in 1-2 Business DaysCadillac Escalade Belt,A/C Compressor

Part Number: 12576447$22.17 MSRP: $39.76You Save: $17.59 (45%)Cadillac Escalade Belt,Fan & Water Pump & Generator & P/S Pump

Part Number: 12626222$34.68 MSRP: $62.20You Save: $27.52 (45%)Ships in 1-3 Business DaysCadillac Escalade Belt, Fan & Water Pump & Generator & P/S Pump

Part Number: 12637202$51.67 MSRP: $92.70You Save: $41.03 (45%)Ships in 1-2 Business DaysCadillac Escalade Belt, Fan

Part Number: 12642433$47.22 MSRP: $84.70You Save: $37.48 (45%)Ships in 1-2 Business DaysCadillac Escalade Belt,Fan & Water Pump & A/C Compressor & Generator & P/S Pump

Part Number: 12576453$51.65 MSRP: $105.92You Save: $54.27 (52%)Ships in 1-2 Business DaysCadillac Escalade Fan Belt

Part Number: 97300653$52.00 MSRP: $93.28You Save: $41.28 (45%)Ships in 1-3 Business DaysCadillac Escalade Belt, Fan

Part Number: 97300657$49.76 MSRP: $108.95You Save: $59.19 (55%)Ships in 1-3 Business DaysCadillac Escalade BELT-ACSRY DRV PRIM

Part Number: 12731926$14.95 MSRP: $26.83You Save: $11.88 (45%)Ships in 1-2 Business DaysCadillac Escalade Belt,A/C Compressor

Part Number: 12576745$19.20 MSRP: $34.43You Save: $15.23 (45%)Cadillac Escalade Belt, Acsry Dr Prim

Part Number: 55490583$34.12 MSRP: $61.20You Save: $27.08 (45%)

| Page 1 of 2 |Next >

1-20 of 29 Results

Cadillac Escalade Drive Belt

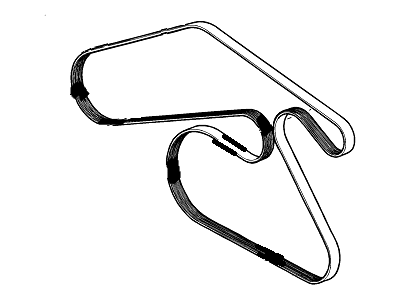

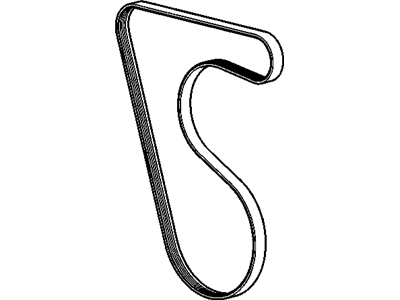

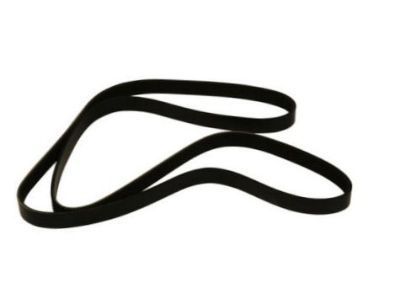

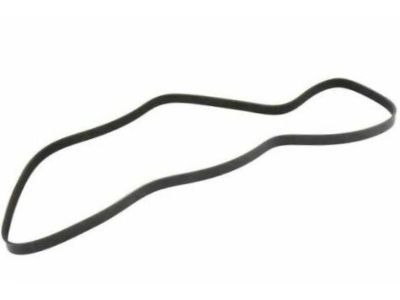

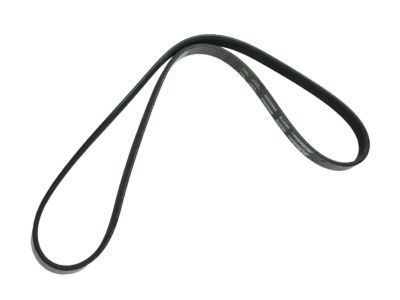

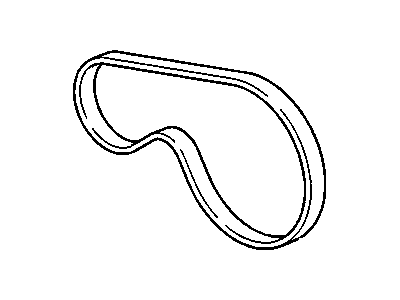

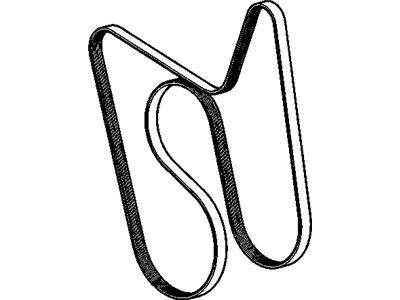

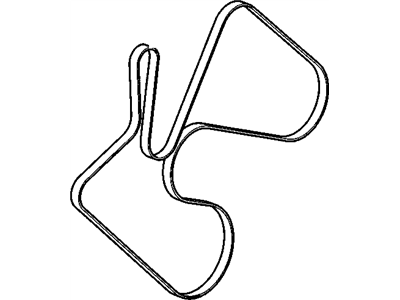

The Drive Belt in Cadillac Escalade vehicles is used for connecting the engine to some other units which include the alternator and the air conditioning compressor. Recently, a serpentine belt is used, which goes round these parts and connects crankshaft pulley to them. This Drive Belt is expected to last for about 100000 miles of usage but then it may need replacement before this time if it shows some signs of damages such as fraying or cracking. The years have seen that Cadillac Escalade models have used drive belts of many kinds such as V belts and multiple groove belts, which have their features. V-belts have good grip and a long service life, whereas, multi-groove belts cut down the restriction and increase the smoothness of the machine. As a result, deciding on which type of Drive Belt is most suitable for Cadillac Escalade may affect the efficacy and durability of the car's performance, which means that it is significant to inspect and replace them on the appropriate time to avoid severe ill of one's engine and additional paraphernalia.

Each OEM Cadillac Escalade Drive Belt we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Cadillac Escalade Drive Belt Parts Questions & Experts Answers

- Q: What is the importance of drive belts and how should they be inspected and replaced on Cadillac Escalade?A:This is sprocket pulley move on the front side of the engine and plays an important role for making the engine work, for driving several components, including the alternator, power steering pump, water pump, vacuum pump, and air conditioning compressor. Several arrangements are possible: a single belt, multiple belts; it is advised to check the belts for wear, despite the fact that they may last more than 100,000 miles. The lead is automatically set to the tension as required by the alternator and power steering and water pump belts, whereas the air conditioning compressor and vacuum pump utilize a "stretchy" belt with no tensioner. Before inspecting the belts, the engine should be turned off, the whole length of the drive belt(s) should be visible and examined for cracks, fraying or glazing of the surface, and the pulleys as well. Minor crack on ribbed belts are permissible as far as they are not serious or they penetrate through the belt's depth. For replacement the air intake duct has to be taken out and the position of the drivebelt has to be noted down before using a breaker bar to loosen the belt and then take it out. The new drivebelt has to be place on the right pulleys and needs to be set down before the air filter duct is put back into its position. The air conditioning compressor drivebelt requires the removal of the accessory drivebelt first, after which the old belt has to be cut or there is specialized tool that has to be deployed. The new belt is then driven on to the crankshaft pulley and slipped over the compressor pulley with a bar that has been inserted between them. The vacuum pump drivebelt is removed in a similar manner as is the new belt positioned correctly on the crankshaft and vacuum pump pulleys. For drivebelt tensioners the drivebelt has to be removed, tensioner removed from the engine and it has to be refitted together with bolts tightened to the prescribed torque.

Related Cadillac Escalade Parts

Browse by Year

2024 Drive Belt 2023 Drive Belt 2022 Drive Belt 2021 Drive Belt 2020 Drive Belt 2019 Drive Belt 2018 Drive Belt 2017 Drive Belt 2016 Drive Belt 2015 Drive Belt 2014 Drive Belt 2013 Drive Belt 2012 Drive Belt 2011 Drive Belt 2010 Drive Belt 2009 Drive Belt 2008 Drive Belt 2007 Drive Belt 2006 Drive Belt 2005 Drive Belt 2004 Drive Belt 2003 Drive Belt 2002 Drive Belt 2000 Drive Belt 1999 Drive Belt