My Garage

My Account

Cart

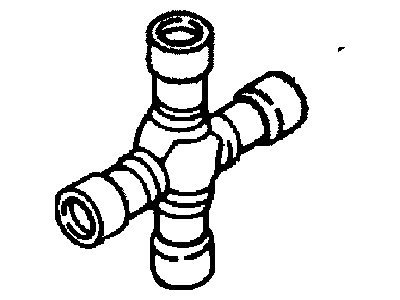

Genuine Chevrolet Astro Universal Joint

U-Joint- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

5 Universal Joints found

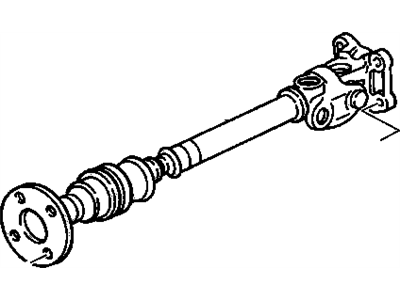

Chevrolet Astro Joint Kit, Front Axle Propeller Shaft Front Universal

Part Number: 23104840$51.58 MSRP: $88.98You Save: $37.40 (43%)Ships in 1-2 Business DaysChevrolet Astro Joint Kit,Front Axle Propeller Shaft Universal

Part Number: 89059111$163.11 MSRP: $273.43You Save: $110.32 (41%)Ships in 1-2 Business DaysChevrolet Astro Joint Kit,Propeller Shaft Flanged Cr Groove

Part Number: 26047645$139.13 MSRP: $549.12You Save: $409.99 (75%)Ships in 1-2 Business DaysChevrolet Astro Joint Kit,Front Axle Propeller Shaft Universal

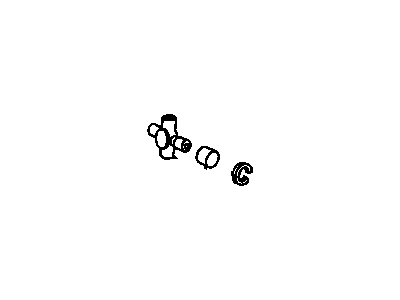

Part Number: 15617322$25.32 MSRP: $40.41You Save: $15.09 (38%)

Chevrolet Astro Universal Joint

The Universal Joint available in Chevrolet Astro vehicles is very important for connecting the driveshaft to differential and it is required to provide some amount of movement when the suspension is working on the contours of the road. This component allows the driveshaft to rotate, to allow changes in the angle between the transmission as well as differential. Usually the Chevrolet Astro Universal Joint is composed of a cross with needle bearings located in steel cups and fixed by clips. From the various Chevrolet Astro cars, some have used the factory recommended pre-lubricated Universal Joints while others have used the ones that provide grease zerks for greasing purposes. The primary difference is that some types can refuel the grease in Universal Joints in case this will serve to prolong the life of a part. A Universal Joint should be checked routinely, and any worn joints make a loud knocking sound or vibrate, and they should be replaced for good vehicle performance.

Each OEM Chevrolet Astro Universal Joint we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Chevrolet Astro Universal Joint Parts Questions & Experts Answers

- Q: What tools and steps are required for replacing a universal joint in a driveshaft on Chevrolet Astro?A:A press or large vise will be needed for this procedure and it may be to the persons benefit to take the driveshaft to a dealer or machine shop to have the universal joint replaced and it should not cost too much money. First of all, it is required to uninstall the driveshaft. Getting into the spider with small pliers, if you have the original front universal joints, be prepared to find that they have plastic injected retainer instead of the rings. When finally reassembling, it is necessary to make use of some snap-rings, which are provided with the new universal joint. Place the driveshaft in a manner whereby its axel is supported and then place it on an arbor press or use a workbench with a vise. Take a piece of pipe or any large socket of the same inside diameter over one of the bearing caps and place the other socket slightly smaller than it on the other cap. When the cap would not come out, or when only part of it sticks out, use the vise or press to force the cap out until it is approximately 0,5mm from the end of the yoke then put this cap between the jaws of the vise or large pliers and remove it gently as it could shear off easily. Take the sockets and move to the other side of the car and press the other side of the bearing cap in the same way. Coat the new universal joint bearings with grease, as indicated, by the servicing kit, or as directed on the manufacturer's instructions. Put the spider in the position in the yoke and screw only one bearing cap partially and then rotate the spider in to the cap and screw only partially the other bearing cap. Position the spider as shown in figure 16-6 and install the bearing caps without damaging the dust seals. Fit the two snap-rings and in case they fail to engage the groove strike the driveshaft yoke lightly with a hammer in order to release tension so that the snap rings can be fitted well. The same steps have also to be followed for replacement of the rear universal joint, but only half of the spider has to be pressed out because two other ends fit directly on the pinion flange with straps and bolts. Last but not the least, fits back the driveshaft and all other components that have been removed earlier.

Related Chevrolet Astro Parts

Browse by Year

2005 Universal Joint 2004 Universal Joint 2003 Universal Joint 2002 Universal Joint 2001 Universal Joint 2000 Universal Joint 1999 Universal Joint 1998 Universal Joint 1997 Universal Joint 1996 Universal Joint 1995 Universal Joint 1994 Universal Joint 1993 Universal Joint 1992 Universal Joint 1991 Universal Joint 1990 Universal Joint 1989 Universal Joint 1988 Universal Joint 1987 Universal Joint 1986 Universal Joint 1985 Universal Joint