My Garage

My Account

Cart

Genuine Chevrolet Beretta Rack And Pinion

Steering Rack And Pinion- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Rack And Pinions found

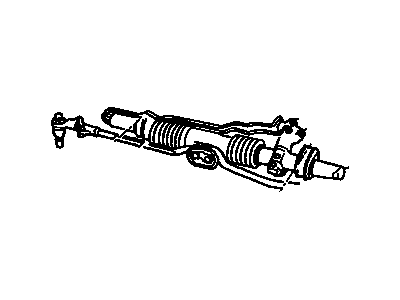

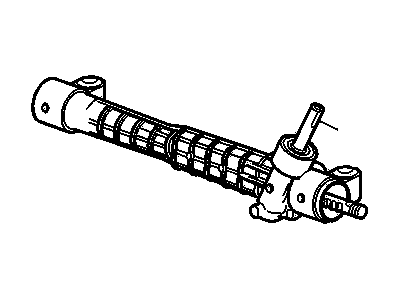

Chevrolet Beretta Rack And Pinion

The Rack And Pinion on Chevrolet BERETTA cars is a device that facilitates the conversion of rotary motion at the steering wheel into the linear movement of the front wheels. The Chevrolet Beretta steering system called the Rack And Pinion has a pinion that is connected to the steering column while the rack gear is housed in a elongated metal tube and moves the wheels in accordance to the inputs that are fed into the steering system. In the course of the production, Chevrolet Beretta models have relied mostly on power assisted rack and pinion steering system, which helped to ease the efforts and improve responsiveness of the vehicle. These systems apply hydraulic pressure in steering and problems can occur such as worn seal and hose or leakages of the fluid. The design generally selects straight gears for smooth running, although helical gears that are cheaper, are likely to cause wear and operational problems. Altogether, the Rack And Pinion that is built-in in the Chevrolet Beretta models is inevitable for controlling the vehicle and assessing the level of the road issuance.

Each OEM Chevrolet Beretta Rack And Pinion we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Chevrolet Beretta Rack And Pinion Parts Questions & Experts Answers

- Q: How Should the Rack and Pinion Assembly Be Removed and Installed on Chevrolet Beretta?A:Specifically, the check engine light cannot work properly if the vehicle has Delco Loe II or Theftlock audio system; you need the activation code of the system and it is better not to disconnect the battery if you have one of these systems. Start stopping the system by removing the cable connection from the negative battery terminal while turning off the lockout if you have a Delco Loe II audio system installed in your vehicle. Take out the left side under-dash panel and undo the at the base of the steering column where there is a boot that rolls back to reveal the flange and the rack and pinion coupler. It is necessary to mark the coupler and the steering column shaft and after that to remove the upper pinch bolt. Next, remove the two left side rack and pinion-to-firewall clamp nuts and the right upper clamp nut. Lose the centre support bracket of the pressure hose retainer on the vehicle rack and also provide a drain pan underneath the car and attend the rack and pinion online pressure line and return line and plug them to avoid loss of the fluid. Yeah, informal, unsophisticated and unschooled but it will suffice to say, turn the front wheel lug nuts slightly counterclockwise, lift the front of the vehicle and then prop it up using jackstands and block the rear wheels. Take off both front wheels, and then loosen the right lower side clamp with the nut, and thereafter, detach the tie-rod ends from the steering arms. Shift the rack and pinion forward, and taking off the lower pinch bolt, the coupler can be slid off the pinion shaft. Support the rack and pinion and taking much care the whole assembly to be brought out through the left side wheel opening. If any mounting studs incurred in clamps, spread thread locking compound on the firewall side of thread and assembled these studs tightly in the firewall. For installation, engage the rack and pinion assembly to pass through the left-wheel opening, get to the approximate position of the assembly, fit the coupler in place before tightening the lower pinch bolt. Align the marking on the coupler housing with those on the steering column shaft, center the rack and pinion and fit the dash seal, while an assistant places the coupler on the shaft. Align the next right side clamp and secure the lower clamp nut to the required torque. Fit the tie-rod ends to the steering arms and fasten nuts to the recommended torque and new cotter pins to be fitted. Fit the front wheels, raise the car and then tighten the nuts in the agreed torque. Bolt the pressure and return lines to the rack and pinion as well as fit the line retainer to the support bracket. Fasten the left side clamp and nuts as well the upper right side clamp nut tightening them to the required torque. Fit in the upper pin and tighten the pinch bolt to the recommended torque and then fit the under-dash panel before reconnecting the battery terminal. Check the type of power steering fluid that your car model requires, and fill the pump accordingly, then bleed the system and also check the level of the fluid while checking for any leakage. Last of all take the vehicle to a dealer service department or an alignment shop.