My Garage

My Account

Cart

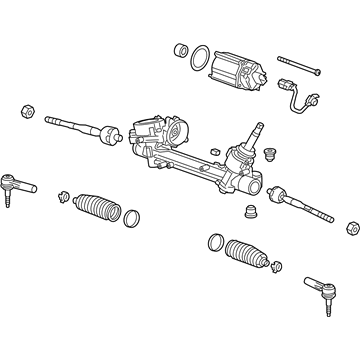

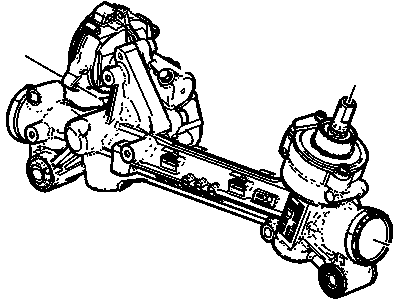

Genuine Chevrolet Rack And Pinion

Steering Rack And Pinion- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

346 Rack And Pinions found

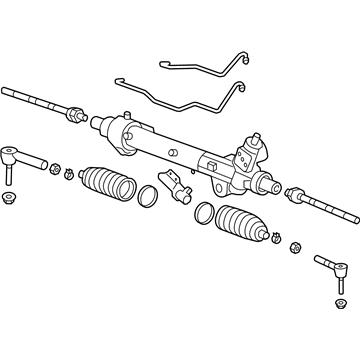

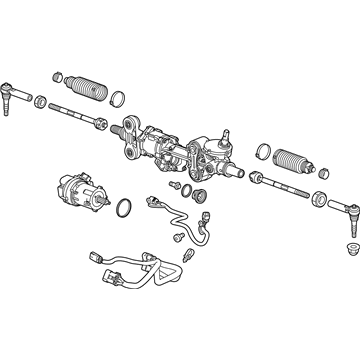

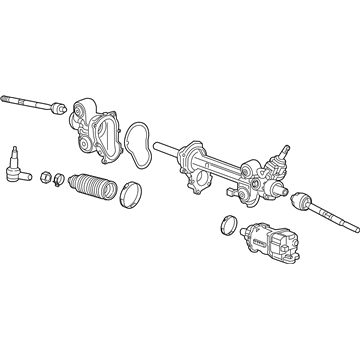

Chevrolet Gear Assembly, R/Pinion Steering

Part Number: 23271566$342.43 MSRP: $585.55You Save: $243.12 (42%)Ships in 1-2 Business DaysProduct Specifications- Other Name: GEAR, Steering; Gear Assembly, Steering Gear

- Replaces: 25789066, 25876163, 25971332, 20843951, 22902261, 20964166, 20817771

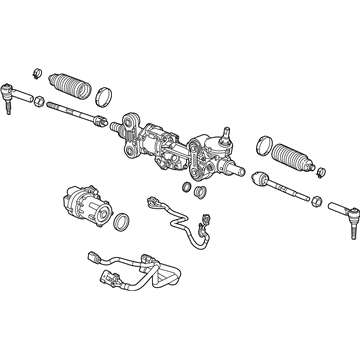

Chevrolet Gear Assembly, R/Pinion Steering

Part Number: 23271562$363.24 MSRP: $1014.82You Save: $651.58 (65%)Ships in 1-3 Business DaysProduct Specifications- Other Name: GEAR, Steering; Gear Assembly, Steering Gear

- Replaces: 20817770, 20843950, 25876162, 20964165, 25971331, 25789067, 22902260

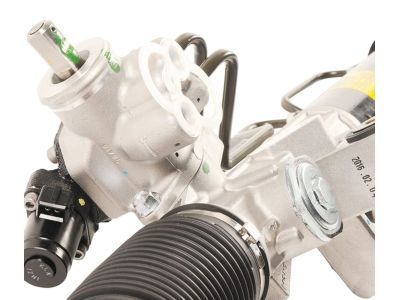

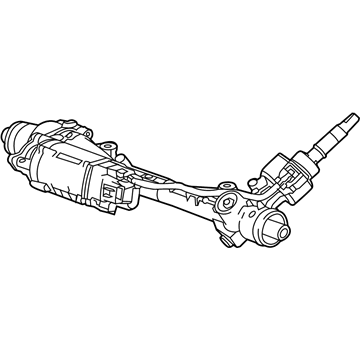

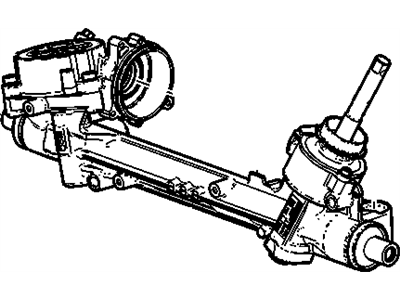

Chevrolet Electric Belt Drive Rack & Pinion Steering Gear

Part Number: 23207196$1983.61 MSRP: $2781.93You Save: $798.32 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: GEAR, Steering; Gear Assembly, Steering Gear

- Replaces: 23118540

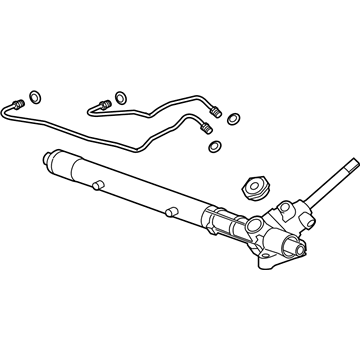

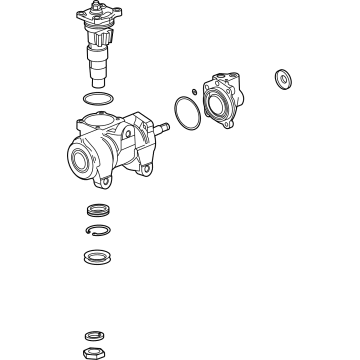

Chevrolet Steering Gear Assembly

Part Number: 22930456$477.80 MSRP: $824.22You Save: $346.42 (43%)Ships in 1-2 Business DaysProduct Specifications- Other Name: GEAR, Steering; Gear Assembly, Steering Gear

- Replaces: 92241184, 20978657, 92233478, 92244725

Chevrolet Electric Belt Drive Rack and Pinion Steering Gear Assembly

Part Number: 84722752$1387.30 MSRP: $2366.81You Save: $979.51 (42%)Product Specifications- Other Name: Gear Assembly, Elec Belt Drv Rack & Pinion Strg; Gear Assembly, Steering Gear

- Replaced by: 86553014

Chevrolet Electric Belt Drive Rack and Pinion Steering Gear Assembly

Part Number: 84774227$1760.77 MSRP: $2447.26You Save: $686.49 (29%)Product Specifications- Other Name: Gear Assembly, Elec Belt Drv Rack & Pinion Strg; Gear Assembly, Steering Gear

- Replaced by: 86553005

Chevrolet Electric Belt Drive Rack and Pinion Steering Gear Assembly

Part Number: 84558550$1070.11 MSRP: $1437.95You Save: $367.84 (26%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Gear Assembly, Elec Belt Drv Rack & Pinion Strg; Gear Assembly, Steering Gear

- Replaced by: 84886553

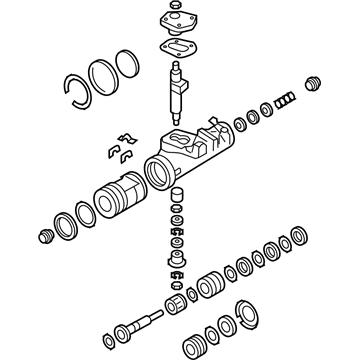

Chevrolet GEAR ASM-HYD RECRG BALL STRG

Part Number: 86802099$846.32 MSRP: $1174.02You Save: $327.70 (28%)Product Specifications- Other Name: Gear Assembly, Steering Gear

- Replaced by: 85734721

- Replaces: 84224694, 84684311, 23372527, 84924574, 84208564, 84625433, 84868032

Chevrolet Electric Belt Drive Rack and Pinion Steering Gear Assembly

Part Number: 84670808$1085.18 MSRP: $1519.91You Save: $434.73 (29%)Product Specifications- Other Name: Gear Assembly, Elec Belt Drv Rack & Pinion Strg; Gear Assembly, Steering Gear

- Replaces: 84498587, 84494276, 22963310, 23353848, 84168691, 84411672

Chevrolet GEAR ASM-HYD RECRG BALL STRG

Part Number: 86825252$1013.76 MSRP: $1969.98You Save: $956.22 (49%)Product Specifications- Replaces: 84228363, 84924576, 84517032, 84563582, 23130417

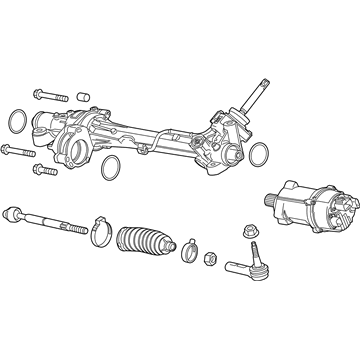

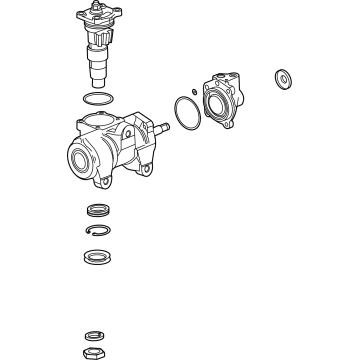

Chevrolet Gear Assembly, Elec Dual Pinion R/Pinion Strg

Part Number: 84216769$3765.45 MSRP: $4886.07You Save: $1120.62 (23%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Gear Assembly, Motor, Steering Gear

- Replaces: 13376583, 22943369, 13349260, 13366875, 13286690, 23338634, 84271183

Chevrolet GEAR ASM-HYD RECRG BALL STRG

Part Number: 85603332$306.22 MSRP: $524.61You Save: $218.39 (42%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Gear Assembly, Steering Gear

- Replaced by: 86285183

- Replaces: 84229219, 84400576, 84209228, 86796122

Chevrolet GEAR ASM,HYD RECRG BALL STRG

Part Number: 19434141$632.77 MSRP: $878.14You Save: $245.37 (28%)Product Specifications- Other Name: Gear Assembly, Steering Gear

- Replaces: 19153560, 19330624, 19167447

Chevrolet Electric Belt Drive Rack and Pinion Steering Gear Assembly

Part Number: 84670807$989.97 MSRP: $1940.65You Save: $950.68 (49%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Gear Assembly, Elec Belt Drv Rack & Pinion Strg

- Replaces: 23353847, 84494275, 84168690, 84450571, 84498586, 22963309

Chevrolet GEAR ASM-HYD RECRG BALL STRG

Part Number: 85603320$796.94 MSRP: $1116.51You Save: $319.57 (29%)Product Specifications- Other Name: Gear Assembly, Steering Gear

- Replaces: 19256662, 19417976, 19330691, 22923381, 22890979, 22756045, 22980021, 84315661, 23453443, 19257732

Chevrolet Electric Belt Drive Rack and Pinion Steering Gear Assembly

Part Number: 84886554$1229.80 MSRP: $1723.06You Save: $493.26 (29%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Gear Assembly, Elec Belt Drv Rack & Pinion Strg

- Replaced by: 86813347

- Replaces: 84233271, 84558551, 23323246

Chevrolet Gear Assembly, Elec Dual Pinion Rack & Pinion S

Part Number: 84710253$2015.13 MSRP: $2826.21You Save: $811.08 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Gear Assembly, Steering Gear

- Replaces: 84163648, 84187572

Chevrolet Gear Assembly, Electric Dual Pinion R/Pinion Steering

Part Number: 84037522$2980.39 MSRP: $4145.40You Save: $1165.01 (29%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Gear Assembly, Elec Dual Pinion R/Pinion Strg; Gear Assembly, Steering Gear

- Replaces: 23142854, 22985119, 22829147

Chevrolet Electric Belt Drive Rack and Pinion Steering Gear Assembly

Part Number: 84774226$1958.39 MSRP: $2527.78You Save: $569.39 (23%)Product Specifications- Other Name: Gear Assembly, Elec Belt Drv Rack & Pinion Strg; Gear Assembly, Steering Gear

- Replaced by: 86553004

Chevrolet Electric Belt Drive Rack and Pinion Steering Gear Assembly

Part Number: 84670795$1047.00 MSRP: $1349.49You Save: $302.49 (23%)Product Specifications- Other Name: Gear Assembly, Elec Belt Drv Rack & Pinion Strg; Gear Assembly, Steering Gear

- Replaces: 84460095, 84411665, 84498595

| Page 1 of 18 |Next >

1-20 of 346 Results

Chevrolet Rack And Pinion

At GMPartsGiant.com, we offer an extensive inventory of genuine Chevrolet Rack And Pinions at competitive prices in the market. All our OEM Chevrolet Rack And Pinions are backed by the manufacturer's warranty and will be shipped promptly to your doorstep. Rest assured, our hassle-free return policy is designed to support you throughout your shopping experience!

Chevrolet Rack And Pinion Parts Questions & Experts Answers

- Q: How to remove and install the rack and pinion and Pitman arm on Chevrolet Caprice?A:Remove the battery ground cable and the coupling shield if applicable. Take off the nuts, lockwashers, and bolts at the steering shaft to coupling flange. Remove the Pitman arm lock nut and washer, marking the position of the Pitman arm in relation to the shaft before using a suitable puller to take it off. Unscrew the Rack And Pinion from the frame and take it out of the vehicle. When installing, position the Rack And Pinion so that the coupling mounts properly to the flanged end of the steering shaft, secure it to the frame, fit the washers and bolts, and then torque-tighten. Secure the steering coupling to the flanged end of the column with the lockwashers and nuts, ensuring the nuts are torque-tightened. Finally, install the Pitman arm and reconnect the battery ground cable along with the coupling shield if applicable.

- Q: How to remove and install the rack and pinion and Pitman arm on Chevrolet El Camino?A:First, disconnect the battery ground, then the nuts, washers, and bolts, tightened at the steering shaft to coupling flange. Subsequently, the lock nut and washer of Pitman arm must be removed and it is essential to mark the position of the Pitman arm in relation to the shaft before using a suitable puller for the removal of Pitman arm. Later remove the Rack And Pinion from the frame by unscrewing the nut and bolts along with taking it out of the car. For installation, align the Rack And Pinion to give correct mounting of the coupling towards the flanged end of the steering shaft, fasten the unit to the frame, fit the washers and bolts and then tighten to the specified torque value. Finally, fasten the steering coupling to the flanged end of the column by lockwashers and nuts in the same way as the engaging nut, and torque-tighten. Last, one places the Pitman arm back in and reconnect the battery ground cable.

- Q: How to diagnose and adjust rack and pinion issues on Chevrolet Nova?A:It is supplied with lubricant for life, and as we only carry out a complete overhaul if there is a severe leakage, refilling will only be called for rarely. To rectify problems of lost motion, slackness and vibration of the Rack And Pinion, one need to: Unscrew the ground terminal of the car battery. Loosen the nut on the Pitman arm and place it aside, note the position of the pitman on the pitman shaft. Having issued these disclaimers, remove the Pitman arm using a suitable puller, then slacken the adjuster plug locknut on the Rack And Pinion and turn the adjusting plug a quarter turn. Pull out the horn button or horn shroud and with full turn to left followed by half a turn to right. With an accurately fitted socket tightened on the centre nut of the steering wheel and detent pin, and a beam or dial type torque wrench, rotate the steering shaft through 90 degrees of its travel, and note the bearing drag as an indication of the thrust bearing pre-load; the party drag should be within the range of 5-9 inch lbs for the earlier models up to 1972 and 4-6 inch lbs for the As a final step turn the plug in the desired position until the right amount of preload is attained, finally tighten the locknut. A irregular staccato feel when the steering wheel is being turned means that the bearings of the Rack And Pinion have worn or are damaged. After that, car's steering wheel from one stop to the other should be turned, with count the number of turn-from, lock to lock TURN, and then the Rack And Pinion is to be turned half of that number to get it to the center. Unscrew the lash adjuster screw locknut and rotate the screw clock wise until all the lash is released between the ball nut and the Pitman shaft sector teeth, tighten the locknut while driving the secrete with the screw. Measure the 'over-center' preload by noting the highest torque at the wheel's centered position; it should be at 4 to 10 in-lbs for models before 1973 and 5 to 9 in-lbs for models on or after 1973, but in any case not less than the value set above. If there are further modifications, which need to be made, the position of the lash adjuster screw can be altered as well. Last of all reconnect the battery ground cable and finally tighten the Pitman arm nut to the specified torque, then reassemble the horn shroud and Pitman arm.

Related Chevrolet Parts

Browse by Model

Astro Rack And Pinion Avalanche Rack And Pinion Aveo Rack And Pinion Beretta Rack And Pinion Blazer EV Rack And Pinion Blazer Rack And Pinion Bolt EUV Rack And Pinion Bolt EV Rack And Pinion C10 Rack And Pinion C1500 Rack And Pinion C20 Rack And Pinion C2500 Rack And Pinion C30 Rack And Pinion C3500 Rack And Pinion Cadet Rack And Pinion Camaro Rack And Pinion Caprice Rack And Pinion Captiva Sport Rack And Pinion Cavalier Rack And Pinion Celebrity Rack And Pinion Chevette Rack And Pinion Citation Rack And Pinion City Express Rack And Pinion Cobalt Rack And Pinion Colorado Rack And Pinion Corsica Rack And Pinion Corvette Rack And Pinion Cruze Rack And Pinion El Camino Rack And Pinion Equinox EV Rack And Pinion Equinox Rack And Pinion Express Rack And Pinion G10 Rack And Pinion G20 Rack And Pinion G30 Rack And Pinion HHR Rack And Pinion Impala Rack And Pinion K10 Rack And Pinion K1500 Rack And Pinion K20 Rack And Pinion K2500 Rack And Pinion K30 Rack And Pinion K3500 Rack And Pinion Lumina Rack And Pinion Malibu Rack And Pinion Metro Rack And Pinion Monte Carlo Rack And Pinion Nova Rack And Pinion Orlando Rack And Pinion P20 Rack And Pinion P30 Rack And Pinion Prizm Rack And Pinion R10 Rack And Pinion R20 Rack And Pinion R2500 Rack And Pinion R30 Rack And Pinion R3500 Rack And Pinion S10 Rack And Pinion SS Rack And Pinion SSR Rack And Pinion Silverado EV Rack And Pinion Silverado Rack And Pinion Sonic Rack And Pinion Spark EV Rack And Pinion Spark Rack And Pinion Spectrum Rack And Pinion Sprint Rack And Pinion Storm Rack And Pinion Suburban Rack And Pinion Tahoe Rack And Pinion Tracker Rack And Pinion Trailblazer Rack And Pinion Traverse Rack And Pinion Trax Rack And Pinion Uplander Rack And Pinion V10 Rack And Pinion V20 Rack And Pinion V30 Rack And Pinion V3500 Rack And Pinion Venture Rack And Pinion Volt Rack And Pinion