My Garage

My Account

Cart

Genuine Pontiac G6 Oil Pan

Oil Drain Pan- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

5 Oil Pans found

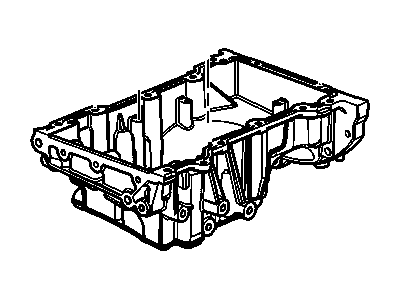

Pontiac G6 Oil Pan

Part Number: 12601240$154.90 MSRP: $267.21You Save: $112.31 (43%)Ships in 1-2 Business DaysPontiac G6 Oil Pan Assembly

Part Number: 12604911$166.01 MSRP: $283.89You Save: $117.88 (42%)Ships in 1-3 Business DaysPontiac G6 Oil Pan Assembly

Part Number: 12603201$188.13 MSRP: $299.93You Save: $111.80 (38%)Ships in 1-3 Business DaysPontiac G6 Oil Pan Assembly

Part Number: 12593455$133.56 MSRP: $220.95You Save: $87.39 (40%)Ships in 1-3 Business Days

Pontiac G6 Oil Pan

The Oil Pan in Pontiac G6 vehicles stores the engine oil and plays the part of distributing the lubricant to other parts of the engine to prevent overheating of parts. Besides, the Pontiac G6 Oil Pan uses a wet sump system where oil that is pulled through a pickup tube by an oil pump, is sent to the various parts of the engine. This design enables the oil to flow down to the Oil Pan after has performed its work of lubricating moving parts of the engine. Traditional Pontiac G6 Oil Pan was of stamped steel, but with modern development they had been manufactured using cast aluminum in most of the models. This change within materials is a great improvement to durability and performance of the products. The Oil Pan's role is to ensure that sufficient quantity of oil is always within the engine needs during several driving situations although it comes with some issues such as oil surging during cornering.

Each OEM Pontiac G6 Oil Pan we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Pontiac G6 Oil Pan Parts Questions & Experts Answers

- Q: How to disconnect the cable from the negative terminal of the battery and remove the oil pan in 3.5L,3.9L V6 engine on Pontiac G6?A:Disconnect the cable from the negative terminal of the battery. If working on a 3.5L engine, install an engine support fixture, raise the vehicle, and support it securely on jackstands. Drain the engine oil and remove the starter. Remove the air conditioning compressor mounting bolts and position it to the side. For 3.9L engines, disconnect the oil level sensor wiring. Remove all transaxle braces from the oil pan and then the oil pan mounting bolts. For 3.5L V6 models, remove the oil filter and its adapter, take the weight off the engine mounts using the engine support fixture, and remove the engine mount bracket from the front passenger side of the engine. Remove the torque converter bolts, ground wires, and wiring brackets from the transaxle. Loosen all transaxle-to-engine bolts a few turns without removing them, then raise the engine/transaxle assembly slightly. Remove the oil pan mounting bolts and pull the engine about 1/2-inch away from the transaxle to allow the oil pan to clear the protruding boss on the transaxle. Carefully separate the oil pan from the block without prying between the block and the pan to avoid damaging the sealing surfaces. Clean the pan with solvent, removing all old sealant and gasket material from the block and pan mating surfaces, and ensure the bolt holes in the block are clear. Apply a bead of RTV sealant to the front of the gasket and each side of the rear main cap, then install the new one-piece oil pan gasket. Place the oil pan in position on the block and install the nuts/bolts, tightening them to the specified torque starting at the center. After tightening the pan-to-block bolts, install the oil pan side bolts and tighten them to torque. For 2007 and later 3.5L models, re-join the engine and transaxle, tightening the bolts to torque, and install the Flywheel/drive plate-to-torque converter bolts. Install the oil pan-to-transaxle brace and torque the bolts to specifications. For 3.9L V6 engines, install the transaxle brace and tighten the bolts to torque. The remaining steps are the reverse of the removal procedure, tightening the subframe bolts to torque. Refill the engine with oil, run it until normal operating temperature is reached, and check for leaks.