My Garage

My Account

Cart

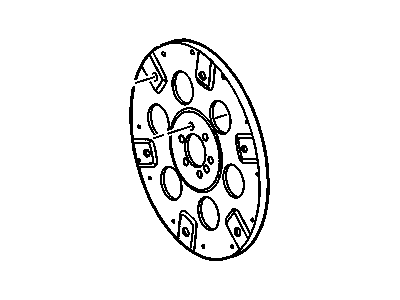

Genuine Chevrolet El Camino Flywheel

Clutch Flywheel- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

5 Flywheels found

Chevrolet El Camino Engine Crankshaft Flywheel

Part Number: 14088765$126.94 MSRP: $210.09You Save: $83.15 (40%)Ships in 1-2 Business DaysChevrolet El Camino Engine Crankshaft Flywheel

Part Number: 471529$140.65 MSRP: $166.69You Save: $26.04 (16%)Ships in 1-2 Business Days

Chevrolet El Camino Flywheel

A Chevrolet El Camino vehicle's Flywheel executes three main duties as it stores engine rotational power for a smoother output and aids the starter drive to spin the crankshaft at ignition while offering a surface for clutch plate friction. Solid Flywheel represent one type while the other version is called dual mass Flywheel (DMFs). Manufacturers maintain two alternatives for Flywheel starting with basic solid designs then moving through DMFs which link separate masses using damping units to both improve performance and decrease noise production. The clutch contact surface of the Flywheel experiences wear that frequently requires replacement and damage to the ring gear becomes another reason for replacing the Chevrolet Flywheel. A limitation exists for performing resurfacing on DMFs thus new El Camino replacement units tend to be the preferred choice. The Chevrolet El Camino relies on its replacement part to run its engine in a smooth way and operate its clutch system effectively.

Each OEM Chevrolet El Camino Flywheel we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Chevrolet El Camino Flywheel Parts Questions & Experts Answers

- Q: How can the flywheel be unbolted from the crankshaft rear flange and properly installed in V8 engine on Chevrolet El Camino?A:Since it's a manual transmission, you'll have to unbolt the clutch housing and clutch before you can take out the transmission, only then can the flywheel be unbolted from the Crankshaft rear flange. To temporarily lock the crankshaft and thus make the work of loosening bolts easier a piece of wood can be inserted between one of the crankshaft throws and the side of the engine block or an alignment tool can be inserted through the flywheel and pushed up against the block. It is recommended that the surfaces to be mated of the flywheel and the crankshaft be cleaned before proceeding to install the flywheel. For the manual transmission type, the flywheel must be to have the dowel hole in the crankshaft matching a dowel hole in the flywheel, for the automatic transmission type, the flywheel has to be installed in a manner that the torque converter attaching pads face the transmission. Tightening of bolts should be done gradually and up to the recommended torque value and where practical it is advisable to use a thread sealant on the bolts. In the same manner, an arrangement of a block of wood or a center punch tool may be placed against the block, so as to prevent the flywheel from rotating during the tightening process.