My Garage

My Account

Cart

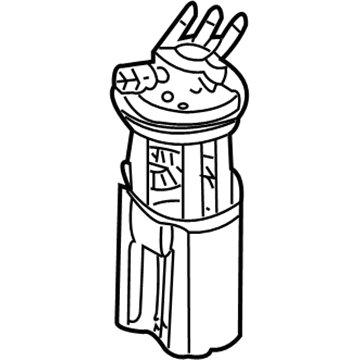

Genuine Chevrolet Fuel Pump

Gas Pump- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

490 Fuel Pumps found

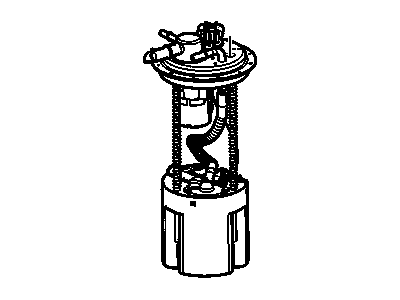

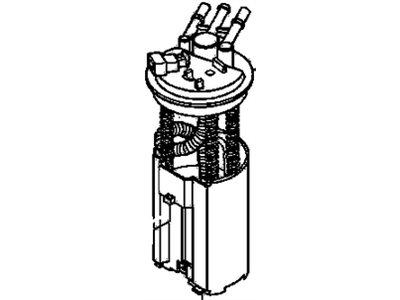

Chevrolet Fuel Pump Assembly

Part Number: 12641847$244.20 MSRP: $504.01You Save: $259.81 (52%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pump Assembly, Fuel ; Pump, Fuel Pump; Fuel Pump

- Replaces: 12639694, 12633423

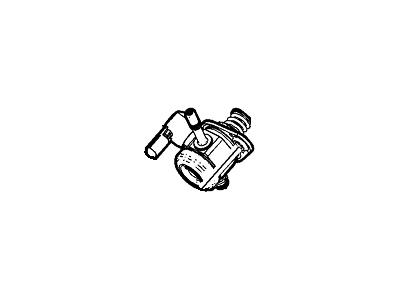

Chevrolet Fuel Pump Assembly

Part Number: 12691016$194.73 MSRP: $401.90You Save: $207.17 (52%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pump Assembly, Fuel; Fuel Pump

- Replaces: 12633594, 12677329, 12669005, 12733943, 12677328, 12641740, 12622475

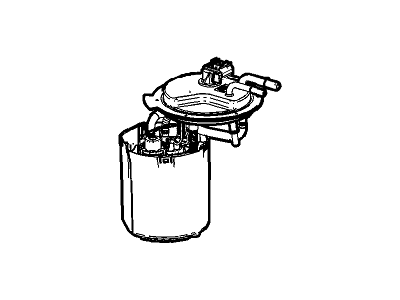

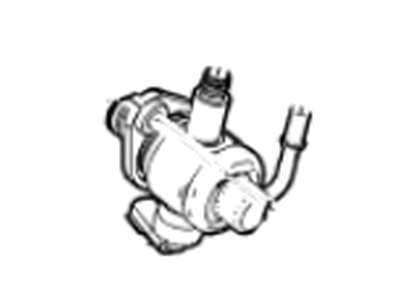

Chevrolet Fuel Tank Fuel Pump Module Kit (W/O Fuel Level Sensor)

Part Number: 19299717$325.12 MSRP: $671.04You Save: $345.92 (52%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Module Kit,Fuel Tank Fuel Pump (W/O Fuel Level Sensor); Fuel Pump, Fuel Pump Assembly

- Replaces: 19259393, 19206650

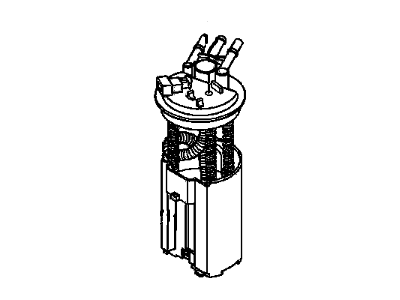

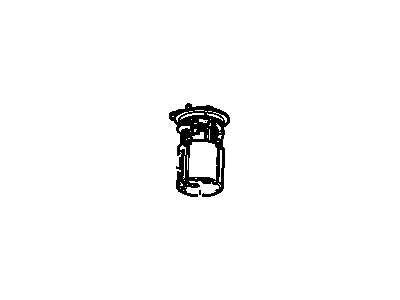

Chevrolet Fuel Tank Fuel Pump Module Kit (W/O Fuel Level Se)

Part Number: 13512934$382.26 MSRP: $789.00You Save: $406.74 (52%)Product Specifications- Other Name: Module Kit, Fuel Tank Fuel Pump (W/O Fuel Level Se); Fuel Pump, Fuel Pump Assembly

- Replaces: 13582493

Chevrolet Fuel Tank Fuel Pump Module Kit

Part Number: 19369915$219.49 MSRP: $414.14You Save: $194.65 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: MODULE KIT,F/TNK F/PMP; Fuel Pump, Module

- Replaces: 19331263, 25345026, 25176865, 19121626, 19153711

Chevrolet Fuel Pump Assembly

Part Number: 12682079$170.98 MSRP: $349.83You Save: $178.85 (52%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pump Assembly, Fuel; Fuel Pump

- Replaces: 12673450, 12649461

- Product Specifications

- Other Name: Pump Assembly, Fuel; Fuel Pump

- Replaces: 12651170, 12676415

Chevrolet MODULE KIT,F/TNK F/PMP (W/O FUEL LVL SEN)

Part Number: 19420858$362.64 MSRP: $741.98You Save: $379.34 (52%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Fuel Pump, Sending Unit

- Replaces: 19149689, 19149228, 19133432, 19417894, 19418613, 19302042, 19354664

Chevrolet Fuel Tank Fuel Pump Module Kit Without Fuel Level Sensor

Part Number: 19299715$357.90 MSRP: $738.69You Save: $380.79 (52%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Module Kit,Fuel Tank Fuel Pump (W/O Fuel Level Sensor); Fuel Pump, Fuel Pump Assembly, Module

- Replaces: 19206481, 19259394

Chevrolet Fuel Tank Fuel Pump Module Kit Without Fuel Level Sensor

Part Number: 13513408$285.84 MSRP: $543.71You Save: $257.87 (48%)Product Specifications- Other Name: Module Kit, Fuel Tank Fuel Pump (W/O Fuel Level Se); Fuel Pump

- Replaced by: 13541364

- Replaces: 13582487

Chevrolet Fuel Tank Fuel Pump Module KIT (W/O Fuel Lvl Sen)

Part Number: 19368768$378.62 MSRP: $781.46You Save: $402.84 (52%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Module Kit,F/Tnk F/Pmp (W/O Fuel Lvl Sen); Fuel Pump, Fuel Pump Assembly

- Replaces: 19256376, 19258819, 19300964, 19181000, 19259398

Chevrolet Fuel Tank Fuel Pump Module Kit

Part Number: 19369943$277.49 MSRP: $572.72You Save: $295.23 (52%)Ships in 1-2 Business DaysProduct Specifications- Other Name: MODULE KIT,F/TNK F/PMP; Fuel Pump, Module

- Replaces: 25314321, 25178961, 19177226, 19331272, 25314323, 25167464

- Product Specifications

- Other Name: Pump Assembly, Fuel; Fuel Pump

- Replaced by: 28290014

- Product Specifications

- Other Name: PUMP ASM,FUEL; Fuel Pump

- Replaced by: 12733320

Chevrolet Fuel Pump Assembly

Part Number: 12691088$180.52 MSRP: $372.59You Save: $192.07 (52%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Pump Assembly, Fuel; Fuel Pump

- Replaces: 12733944, 12647366, 12673750, 12673141

- Product Specifications

- Other Name: Fuel Pump, Injection Pump

- Replaces: 55493585

Chevrolet MODULE KIT,F/TNK F/PMP (W/O FUEL LVL SEN)

Part Number: 19418261$286.78 MSRP: $591.91You Save: $305.13 (52%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Fuel Pump, Fuel Pump Assembly, Sending Unit

- Replaces: 19153374, 88967148, 88967149

Chevrolet Fuel Tank Fuel Pump Module Kit

Part Number: 19370394$395.05 MSRP: $711.80You Save: $316.75 (45%)Product Specifications- Other Name: Module Kit,F/Tnk F/Pmp; Fuel Pump, Module

- Replaces: 19207716, 19168126, 19149062, 19256621, 88965556

- Product Specifications

- Other Name: Pump,Fuel

- Replaces: 25163470, 25116167, 25163471

Chevrolet Fuel Tank Fuel Pump Module Kit

Part Number: 19370396$342.10 MSRP: $616.40You Save: $274.30 (45%)Product Specifications- Other Name: MODULE KIT,F/TNK F/PMP; Fuel Pump, Module

- Replaces: 19168774, 19256622, 88983122, 89060651, 19149059, 19207718, 88965555, 88983254

| Page 1 of 25 |Next >

1-20 of 490 Results

Chevrolet Fuel Pump

At GMPartsGiant.com, we offer an extensive inventory of genuine Chevrolet Fuel Pumps at competitive prices in the market. All our OEM Chevrolet Fuel Pumps are backed by the manufacturer's warranty and will be shipped promptly to your doorstep. Rest assured, our hassle-free return policy is designed to support you throughout your shopping experience!

Chevrolet Fuel Pump Parts Questions & Experts Answers

- Q: How to remove and install a Fuel Pump on Chevrolet Astro?A:The carburetor models' mechanical pump is a sealed unit that is non-rebuildable. It is positioned at the front on the right side of the engine. To remove the pump, you have to first disconnect the battery's earth cable and disconnect it from the circuit. After that, one can remove by loosening the fuel inlet hose, outlet line, and vapor return hose (if present). Take out two mounting bolts and take off fuel pump being careful to retrieve pushrod. Remove gasket and mounting plate and clean block mounting surface. To hold pushrod in position during installation, apply grease. Put new gasket, mounting plate and pump on block and tighten bolts securely. Securely connect inlet hose, outlet line as well as vapor return hose after that. When you reattach the hoses remember to properly tighten them. Finally, start up the engine to find out any possible leakage of fuel at any of these hose or line joints. For electric pumps in fuel injected models, perform a fuel pressure relief procedure and disconnect the battery cable. When removing it, mark properly for later reinstallation of fuel tank so as to reinstall it correctly later. This assembly is held to the fuel tank with a cam lock ring or snap-ring depending on model type. Take off this assembly from the tank cautiously while taking care not damage its float arm if possible. If needed change rubber gasket or O-ring and also check if necessary replace fuel strainer due to damage or clogs inside that filter screen element of this part of system assembly before reassembly process begins again in step 3 above but after first removing old one using hand tool like screwdriver handle perhaps before starting disassembling stage consisting putting new manufacturer's instructions specified machine into assembly for another such product purchased year ago installing company made spare component called mount mark 1 etc which come packed tightly within cardboard box having some tape seals across topsides open end where customer opens before starting. Therefore, remove assembly of fuel pump/sending unit into tank by aligning match-marks and snap-ring or cam lock ring lastly followed by assembly of fuel tank installation.

- Q: How does the fuel pump operate and what steps should be taken to test it for faults on Chevrolet Caprice?A:The fuel pump is a sealed type actuated from the engine camshaft, utilizing a pushrod between the camshaft and the pump rocker, while 231 V6 engines have pumps driven directly from the camshaft eccentric without a pushrod. Servicing is not possible due to the sealed nature of the unit, but if a fault is suspected, a test can be performed. First, ensure there is gas in the fuel tank and disconnect the primary wire between the coil and the distributor to prevent engine firing when the starter motor is engaged for models from 1969 to 1974; for models from 1975 to 1981, disconnect the distributor wiring marked 'BAT'. Next, disconnect the fuel line from the carburetor and place its open end in a container. Finally, operate the starter motor and observe for well-defined spurts of fuel ejected from the open end of the line; if present, the pump is functioning correctly, otherwise, it should be replaced.

- Q: How to disconnect and replace the fuel pump on Chevrolet Tracker?A:Disconnect the cable from the negative terminal of the battery and relieve the fuel system pressure. For mechanical pumps in carbureted vehicles, relieve the fuel tank pressure by removing the fuel filler cap, then locate the fuel pump mounted on the right rear corner of the cylinder head. Place rags underneath the pump to catch any spilled fuel, loosen the hose clamps, and disconnect the hoses using a twisting motion while plugging them immediately to prevent leakage and dirt entry. Unscrew the fasteners retaining the pump to the cylinder head, detach the pump, and inspect the pump pushrod for wear, replacing it if necessary and coating it with clean engine oil before installation. Remove all traces of old gasket material from the mating surfaces on the cylinder head and the fuel pump if it will be reinstalled, taking care not to gouge the soft aluminum surfaces. Installation is the reverse of removal, ensuring a new gasket is used and the mounting fasteners are tightened to the specified torque. For electric pumps in fuel-injected vehicles, remove the fuel tank and unscrew the six bolts securing the fuel pump flange, then lift the assembly out of the fuel tank. Remove the pump from its bracket, disconnect the electrical connectors while noting their positions, and push the nozzle of the new pump into the coupling hose before inserting the bottom of the pump into its bracket and connecting the wires to the proper terminals. If the filter at the bottom of the pump appears dirty, replace it, and complete the installation by reversing the removal process, ensuring to replace the pump unit sealing O-ring if it shows any signs of deterioration.

Related Chevrolet Parts

Browse by Model

Astro Fuel Pump Avalanche Fuel Pump Aveo Fuel Pump Beretta Fuel Pump Blazer Fuel Pump C10 Fuel Pump C1500 Fuel Pump C20 Fuel Pump C2500 Fuel Pump C30 Fuel Pump C3500 Fuel Pump Cadet Fuel Pump Camaro Fuel Pump Caprice Fuel Pump Captiva Sport Fuel Pump Cavalier Fuel Pump Celebrity Fuel Pump Chevette Fuel Pump Citation Fuel Pump City Express Fuel Pump Cobalt Fuel Pump Colorado Fuel Pump Corsica Fuel Pump Corvette Fuel Pump Cruze Fuel Pump El Camino Fuel Pump Equinox Fuel Pump Express Fuel Pump G10 Fuel Pump G20 Fuel Pump G30 Fuel Pump HHR Fuel Pump Impala Fuel Pump K10 Fuel Pump K1500 Fuel Pump K20 Fuel Pump K2500 Fuel Pump K30 Fuel Pump K3500 Fuel Pump Lumina Fuel Pump Malibu Fuel Pump Metro Fuel Pump Monte Carlo Fuel Pump Orlando Fuel Pump P20 Fuel Pump P30 Fuel Pump Prizm Fuel Pump R10 Fuel Pump R20 Fuel Pump R2500 Fuel Pump R30 Fuel Pump R3500 Fuel Pump S10 Fuel Pump SS Fuel Pump SSR Fuel Pump Silverado Fuel Pump Sonic Fuel Pump Spark Fuel Pump Spectrum Fuel Pump Sprint Fuel Pump Suburban Fuel Pump Tahoe Fuel Pump Tracker Fuel Pump Trailblazer Fuel Pump Traverse Fuel Pump Trax Fuel Pump Uplander Fuel Pump V10 Fuel Pump V20 Fuel Pump V30 Fuel Pump V3500 Fuel Pump Venture Fuel Pump Volt Fuel Pump