My Garage

My Account

Cart

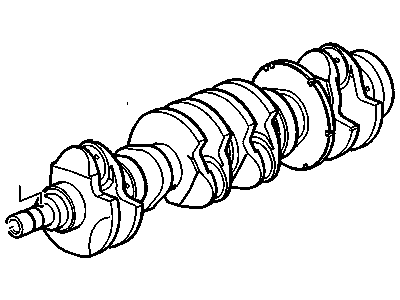

Genuine Chevrolet Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

127 Crankshafts found

Chevrolet Crankshaft

Part Number: 12661875$582.24 MSRP: $1004.39You Save: $422.15 (43%)Ships in 1-3 Business DaysProduct Specifications- Replaces: 12617226, 12621352, 12623075, 12601938

- Product Specifications

- Other Name: Crankshaft Asm ; Crankshaft, Engine; Crankshaft

- Replaced by: 12736807

Chevrolet Crankshaft Assembly

Part Number: 12578164$685.29 MSRP: $1134.22You Save: $448.93 (40%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Crankshaft Asm; Crankshaft

- Replaces: 12578182, 12623302

Chevrolet Engine Crankshaft

Part Number: 55574335$204.27 MSRP: $337.94You Save: $133.67 (40%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Crankshaft Asm ; Crankshaft, Engine; Crankshaft

- Product Specifications

- Other Name: Crankshaft Asm ; Crankshaft, Engine; Crankshaft

- Product Specifications

- Replaces: 12616835, 12610050

Chevrolet Engine Crankshaft

Part Number: 12623074$564.05 MSRP: $933.17You Save: $369.12 (40%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Crankshaft Asm ; Crankshaft, Engine; Crankshaft

- Replaces: 12571127, 12601939, 12621351, 12621353

- Product Specifications

- Other Name: Crankshaft Asm; Crankshaft

- Replaces: 12629940

- Product Specifications

- Other Name: Crankshaft Assembly, .; Crankshaft

- Replaces: 12619781

Chevrolet CRANKSHAFT ASM,.

Part Number: 19431873$461.48 MSRP: $763.62You Save: $302.14 (40%)Ships in 1-3 Business DaysProduct Specifications- Replaces: 12685659, 12597569, 12584997

- Product Specifications

- Other Name: Crankshaft Assembly, .; Crankshaft

- Replaces: 12676729, 12646883

Chevrolet Engine Crankshaft

Part Number: 12598044$359.11 MSRP: $567.58You Save: $208.47 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Crankshaft Asm ; Crankshaft, Engine; Crankshaft

Chevrolet Crankshaft

Part Number: 12661873$526.44 MSRP: $900.16You Save: $373.72 (42%)Ships in 1-2 Business DaysProduct Specifications- Replaces: 12630898

- Product Specifications

- Other Name: Crankshaft Asm ; Crankshaft, Engine; Crankshaft

- Product Specifications

- Other Name: Crankshaft Assembly, .; Crankshaft

- Replaces: 12635333, 12641925

Chevrolet Engine Crankshaft

Part Number: 14088526$555.37 MSRP: $670.13You Save: $114.76 (18%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Crankshaft, Engine; Crankshaft

- Replaces: 14088527

Chevrolet Crankshaft Assembly

Part Number: 12664179$792.70 MSRP: $1311.98You Save: $519.28 (40%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Crankshaft Assembly, .; Crankshaft

- Product Specifications

- Other Name: Crankshaft Asm ; Crankshaft, Engine; Crankshaft

- Replaces: 89060401

- Product Specifications

- Other Name: Crankshaft, Engine; Crankshaft

- Product Specifications

- Other Name: Crankshaft Assembly, .; Crankshaft

- Replaced by: 55512256

| Page 1 of 7 |Next >

1-20 of 127 Results

Chevrolet Crankshaft

At GMPartsGiant.com, we offer an extensive inventory of genuine Chevrolet Crankshafts at competitive prices in the market. All our OEM Chevrolet Crankshafts are backed by the manufacturer's warranty and will be shipped promptly to your doorstep. Rest assured, our hassle-free return policy is designed to support you throughout your shopping experience!

Chevrolet Crankshaft Parts Questions & Experts Answers

- Q: What steps must be taken to remove the crankshaft from the engine after it has been taken out on Chevrolet Astro?A:The crankshaft can only be removed after the engine has been taken out of the vehicle, assuming that the flywheel or driveplate, vibration damper/crankshaft pulley hub, timing chain (for V6 engines), oil pan, oil pump, and piston/connecting rod assemblies have been detached. For engines with a one-piece rear main oil seal, the seal housing must be unbolted from the block prior to crankshaft removal. First, check the end play by mounting a dial indicator aligned with the crankshaft and touching one of the crank throws. Push the crankshaft to the rear and zero the dial indicator, then pry it to the front and note the reading, which indicates the end play. If the end play exceeds specifications, inspect the thrust surfaces for wear; if no wear is found, new main bearings may resolve the issue. If a dial indicator is unavailable, feeler gauges can be used by prying the crankshaft to the front and measuring the clearance between the crankshaft and the thrust main bearing. Check the main bearing caps for markings indicating their locations, numbering them consecutively from front to rear if necessary, and loosen the bolts gradually until they can be removed by hand. Gently tap the caps with a soft-face hammer to separate them from the block, using the bolts as levers if needed, and take care not to drop the bearing inserts. Finally, lift the crankshaft out of the engine, ideally with assistance, and return the bearing inserts to their positions in the block and main bearing caps, tightening the bolts finger tight.

- Q: How to remove the Crankshaft Seal and Crankshaft in V8 engine on Chevrolet Caprice?A:The crankshaft and main bearings ought not to be removed except when the engine has been removed from the car, and the engine should initially be dismantled. It is advisable that each of the five main bearing caps should be labeled to show where they belong in the engine block; if this is done, indentations as would be done with the connecting rods and caps should be made. After loosening the main bearing caps they should each be removed from the crankshaft with their corresponding bearing and should be laid on another work bench numbered as per the position of the bearing caps on the engine. The crankshaft can then be slowly pulled out with the use of lifters so as not to wreck the engine block. The two halve of the rear main bearing oil seal has to be detached, The crank shaft main bearings together with the cylinder block and main bearing caps should be withdrawn in such a manner that they will not be mixed since they have their own positions. Last, the crankshaft gear at the front must be removed which is best to be done with a puller intended for this job.

- Q: How to inspect and repair a crankshaft on Chevrolet Tracker?A:Remove all burrs from the crankshaft oil holes with a stone, file or scraper, ensuring the oil holes are chamfered to prevent damage to new bearings. Check the main and connecting rod bearing journals for uneven wear, scoring, pits and cracks. Rub a penny across each journal several times to reveal its condition-if copper rubs off and is embedded in the crankshaft, the journals should be reground. Clean the crankshaft with solvent and dry it with compressed air, using a stiff brush to clean the oil holes and flush them with solvent. Check the rest of the crankshaft for cracks and other damage, which should be revealed by mag-nafluxing. Measure the diameter of the main and connecting rod journals with a micrometer and compare the results to the Specifications. If the crankshaft journals are damaged, tapered, out of round or worn beyond the limits given in the Specifications, have the crankshaft reground by an automotive machine shop and use the correct size bearing inserts if the crankshaft is reconditioned. Check the oil seal journals at each end of the crankshaft for wear and damage. If the seal has worn a groove in the journal, or if it's nicked or scratched, the new seal may leak when the engine is reassembled. In some cases, an automotive machine shop may be able to repair the journal by pressing on a thin sleeve. If repair isn't feasible, a new or different crankshaft should be installed. Examine the main and rod bearing inserts.

Related Chevrolet Parts

Browse by Model

Astro Crankshaft Avalanche Crankshaft Aveo Crankshaft Beretta Crankshaft Blazer Crankshaft C10 Crankshaft C1500 Crankshaft C20 Crankshaft C2500 Crankshaft C30 Crankshaft C3500 Crankshaft Cadet Crankshaft Camaro Crankshaft Caprice Crankshaft Captiva Sport Crankshaft Cavalier Crankshaft Celebrity Crankshaft Citation Crankshaft City Express Crankshaft Cobalt Crankshaft Colorado Crankshaft Corsica Crankshaft Corvette Crankshaft Cruze Crankshaft El Camino Crankshaft Equinox Crankshaft Express Crankshaft G10 Crankshaft G20 Crankshaft G30 Crankshaft HHR Crankshaft Impala Crankshaft K10 Crankshaft K1500 Crankshaft K20 Crankshaft K2500 Crankshaft K30 Crankshaft K3500 Crankshaft Lumina Crankshaft Malibu Crankshaft Metro Crankshaft Monte Carlo Crankshaft Nova Crankshaft P20 Crankshaft P30 Crankshaft Prizm Crankshaft R10 Crankshaft R20 Crankshaft R2500 Crankshaft R30 Crankshaft R3500 Crankshaft S10 Crankshaft SS Crankshaft SSR Crankshaft Silverado Crankshaft Sonic Crankshaft Spark Crankshaft Spectrum Crankshaft Sprint Crankshaft Storm Crankshaft Suburban Crankshaft Tahoe Crankshaft Tracker Crankshaft Trailblazer Crankshaft Traverse Crankshaft Trax Crankshaft Uplander Crankshaft V10 Crankshaft V20 Crankshaft V30 Crankshaft V3500 Crankshaft Venture Crankshaft Volt Crankshaft